Surface processing with laser

Contract manufacturing

Our services

Hardening · Repairing · Cladding

Repair and

cladding

Hardening

Sample production and verification

Additive

manufacturing

For demanding components

Surface processing with laser

We harden and repair your components or make design changes and correct production errors as well as additive manufacturing of 3D components.

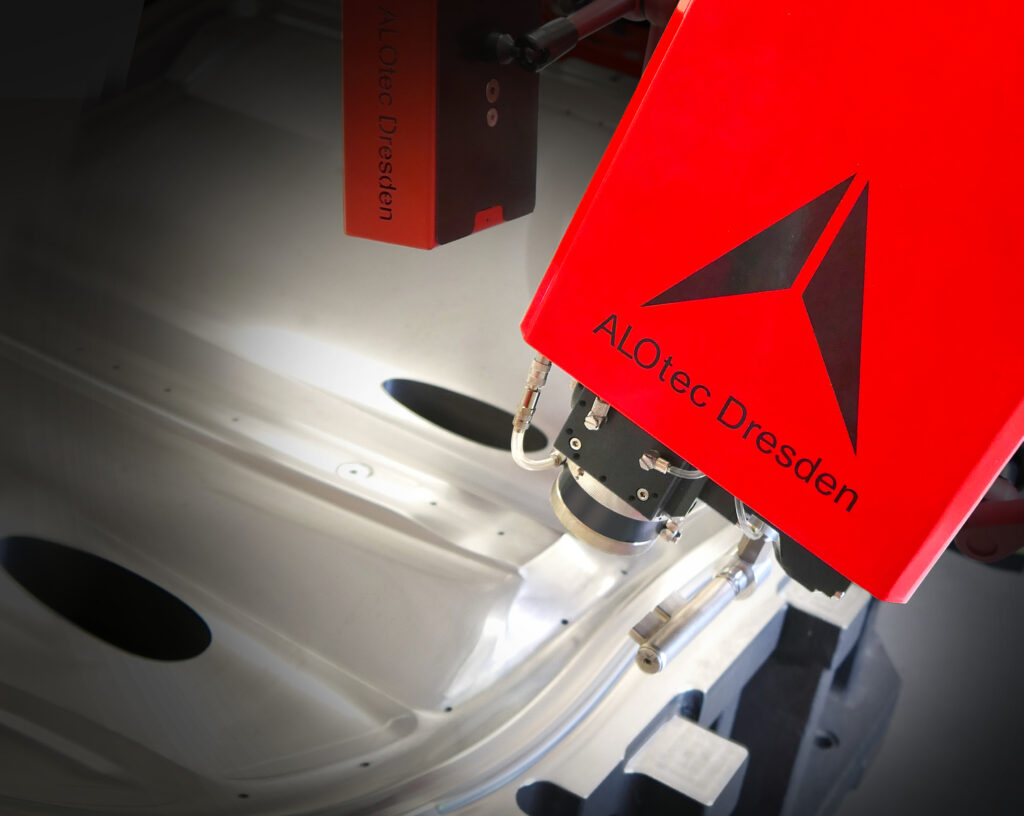

Laser processing directly at your site

We offer laser processing directly on the component at your site. This eliminates transport and set-up times for the component as well as the associated costs and risks.

We are happy to advise you!

Our materials specialists will quickly find the best solution for your requirements.

Laser cladding

Repair and cladding

Different processes are used in laser cladding for repair, cladding and additive manufacturing, depending on the component and requirements. Cladding can be carried out with powder or with wire as a filler material.

Areas of application:

![]() Industry and agriculture

Industry and agriculture

![]() Automotive, railway and shipbuilding

Automotive, railway and shipbuilding

![]() Machine, tool and mould making

Machine, tool and mould making

![]() Oil and gas industry, mining

Oil and gas industry, mining

![]() Additive manufacturing of 3D components

Additive manufacturing of 3D components

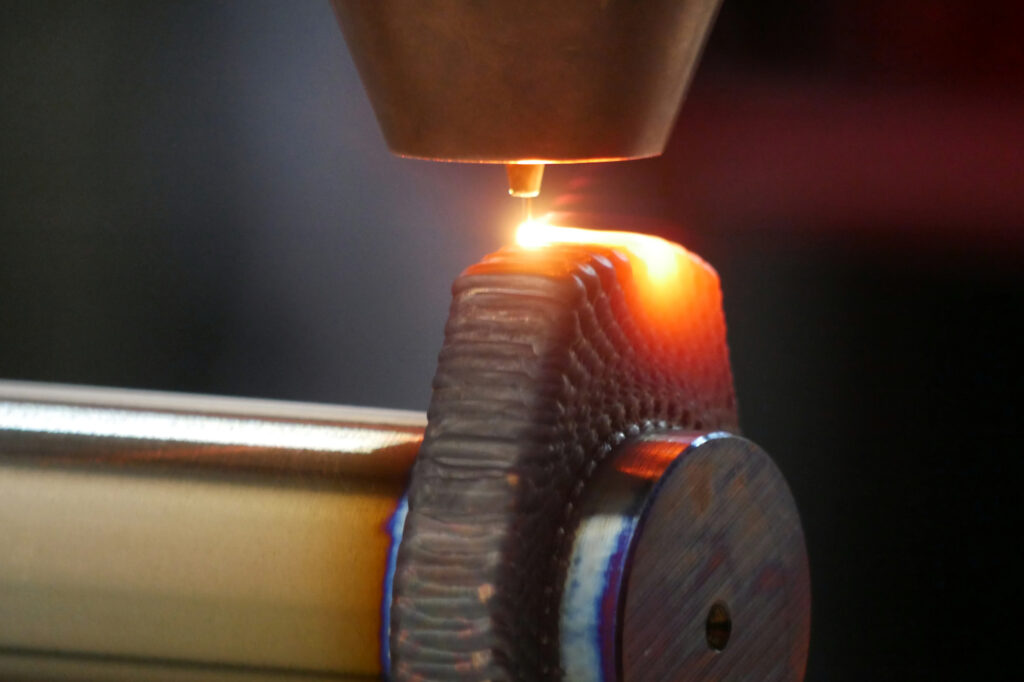

Laser cladding with powder

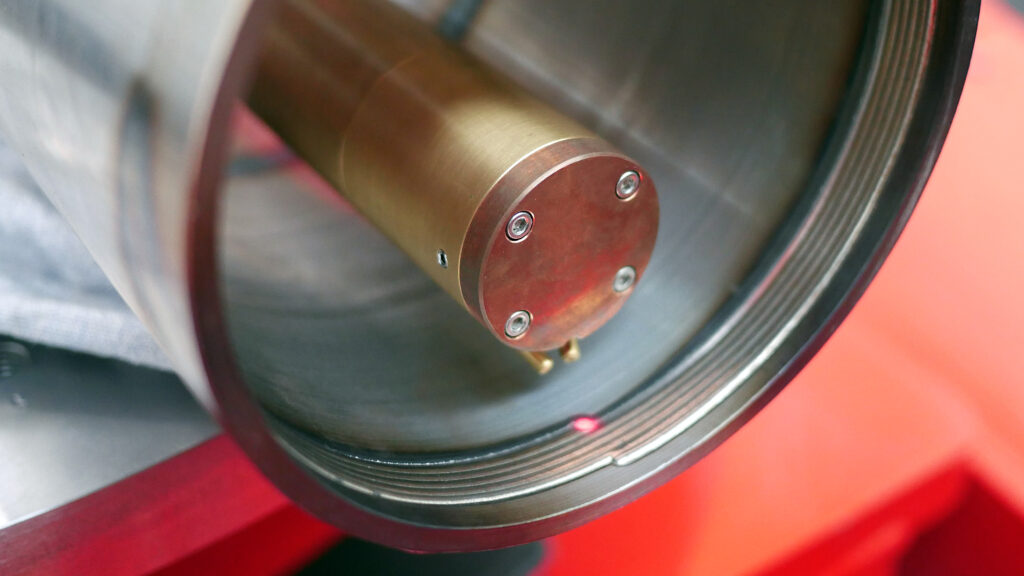

ALOpowder laser cladding is a manufacturing process in which the laser beam melts a base material on the surface and a powdered filler material is introduced into the molten pool via a nozzle.

Various processing optics with a fixed or variable laser track width and an optic for internal coating ensure optimum surface processing.

Advantages of powder cladding:

![]() Hardness up to 65 HRC, tungsten carbides up to 3000 HV

Hardness up to 65 HRC, tungsten carbides up to 3000 HV

![]() Low distortion due to low heat input

Low distortion due to low heat input

![]() Flexible shaping of the laser beam

Flexible shaping of the laser beam

![]() Process control with time-parallel documentation

Process control with time-parallel documentation

![]() Energy-efficient and environmentally friendly

Energy-efficient and environmentally friendly

![]() Wide range of alloys

Wide range of alloys

![]() Application rate of up to 5 kg/h

Application rate of up to 5 kg/h

![]() Internal cladding from 80 mm diameter

Internal cladding from 80 mm diameter

![]() Also suitable for small batches and individual pieces

Also suitable for small batches and individual pieces

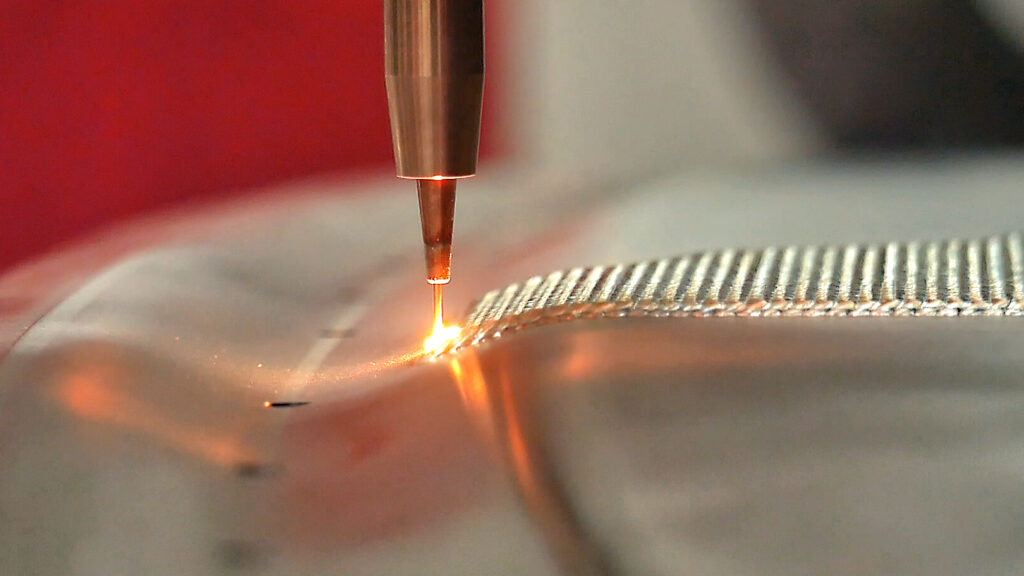

Cladding with wire

In ALOwire laser wire cladding, the laser beam is split into individual beams using optical elements. These create a localised molten pool on the surface of the base material, into which a wire is fed concentrically.

Advantages of wire cladding:

![]() Hardness up to 66 HRC

Hardness up to 66 HRC

![]() Low distortion due to low heat input

Low distortion due to low heat input

![]() Process control independent of direction

Process control independent of direction

![]() Process control with time-parallel documentation

Process control with time-parallel documentation

![]() Energy-efficient and environmentally friendly

Energy-efficient and environmentally friendly

![]() Optimum filler materials

Optimum filler materials

![]() Application rate of up to 1.5 kg/h

Application rate of up to 1.5 kg/h

![]() Also suitable for small batches and individual pieces

Also suitable for small batches and individual pieces

Hardness and precision

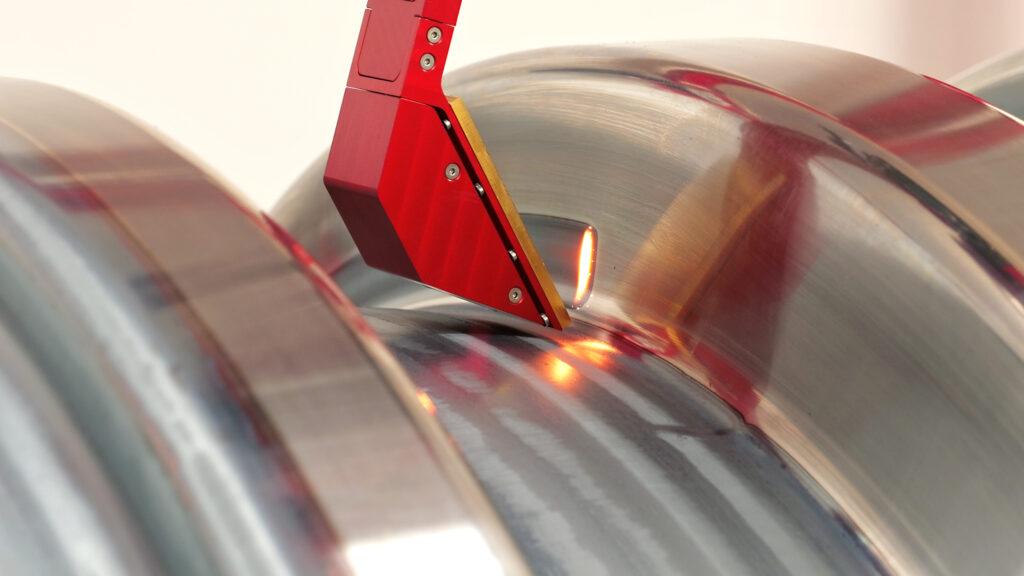

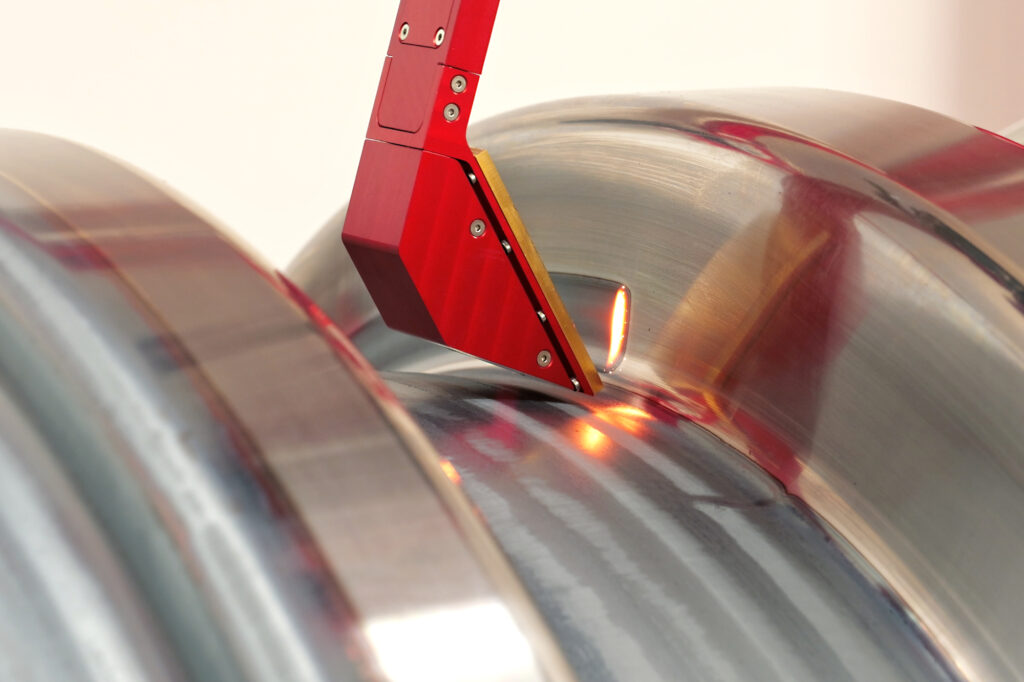

Laser hardening with ALOhard

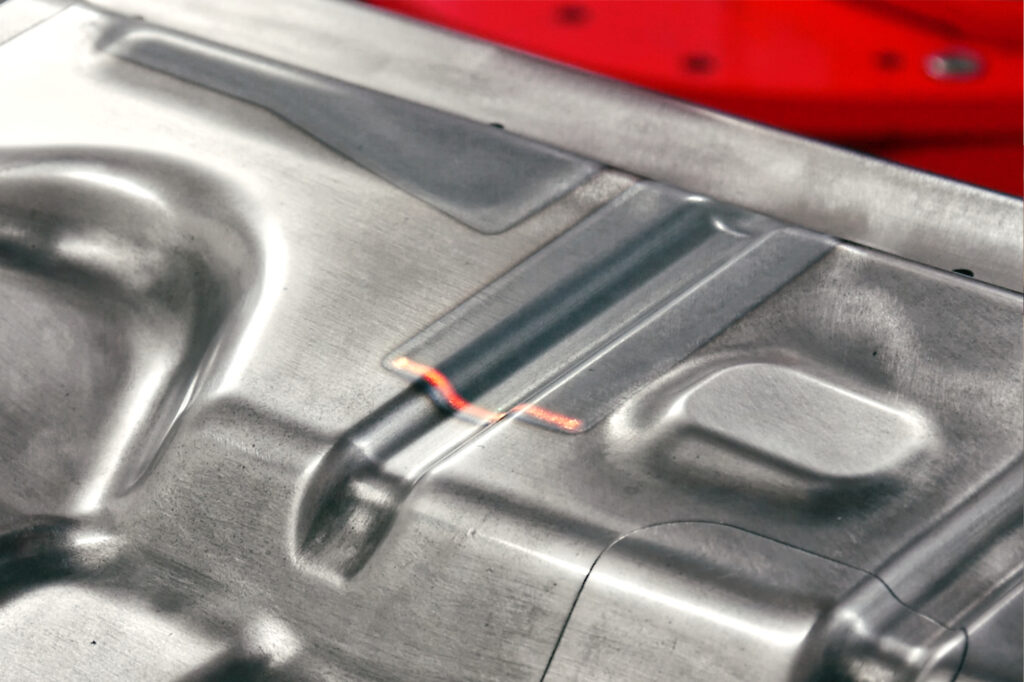

Laser hardening is a surface hardening process that produces maximum hardness values on the component surface with a very low energy input. This achieves a specific improvement in the wear behaviour of components.

Due to its technology, laser hardening is very environmentally friendly and resource-saving and is very economical, especially in the area of small series and individual parts.

Advantages of laser hardening:

![]() High surface hardness with a tough material core

High surface hardness with a tough material core

![]() Low distortion process

Low distortion process

![]() Consistent surface temperature

Consistent surface temperature

![]() Energy-efficient and environmentally friendly

Energy-efficient and environmentally friendly

![]() No quenching media required

No quenching media required

![]() Also suitable for small batches and individual pieces

Also suitable for small batches and individual pieces

![]() Process control with parallel documentation

Process control with parallel documentation

Areas of application:

ALOhard laser hardening is used for finishing highly stressed, complex components. Maximum hardness values are generated on the component surface with low energy input. This specifically improves the wear behavior of highly stressed component surfaces.

![]() Industry and agriculture

Industry and agriculture

![]() Automotive, railroad and shipbuilding

Automotive, railroad and shipbuilding

![]() Machine, tool and mold making

Machine, tool and mold making

![]() Oil and gas industry, mining

Oil and gas industry, mining

Laser hardening 5.0

Laser hardening with ALOhardscan regardless of the component geometry: radii, V-grooves, multiple steps or edges using the dynamic, scan-like oscillating movement of an oscillating mirror.

Hardening with mirrors

With the mirror system, we can reach difficult areas such as deep-drawn edges or internal surfaces of cylinders or tubes during laser hardening.

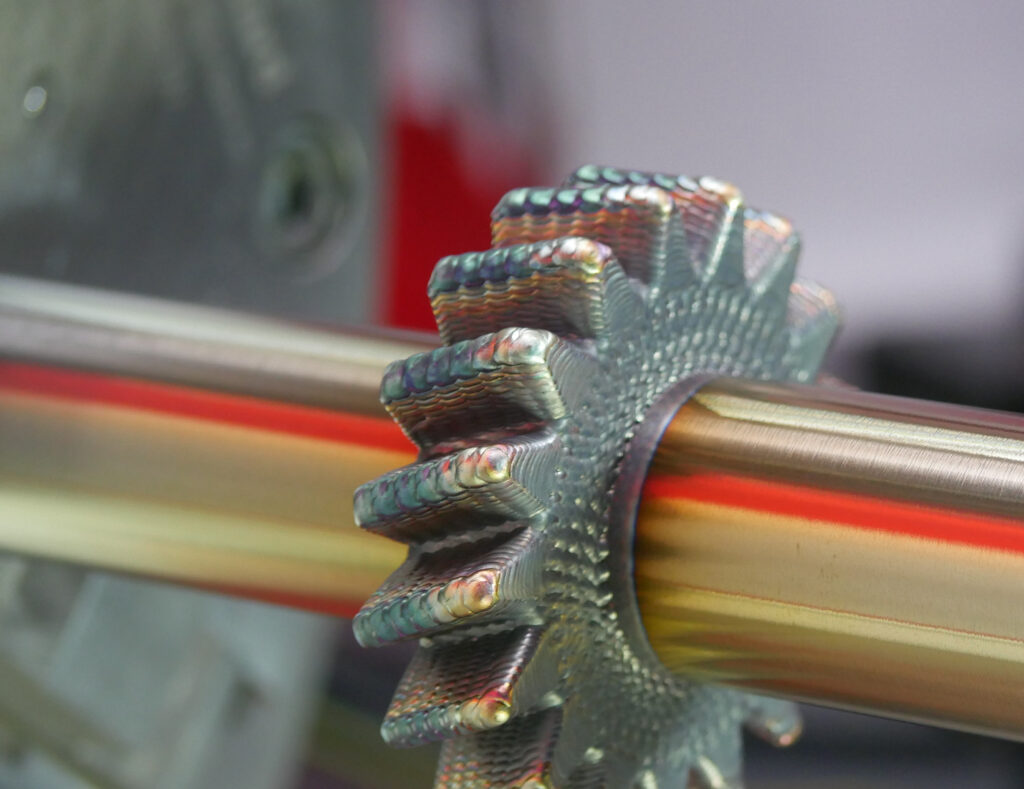

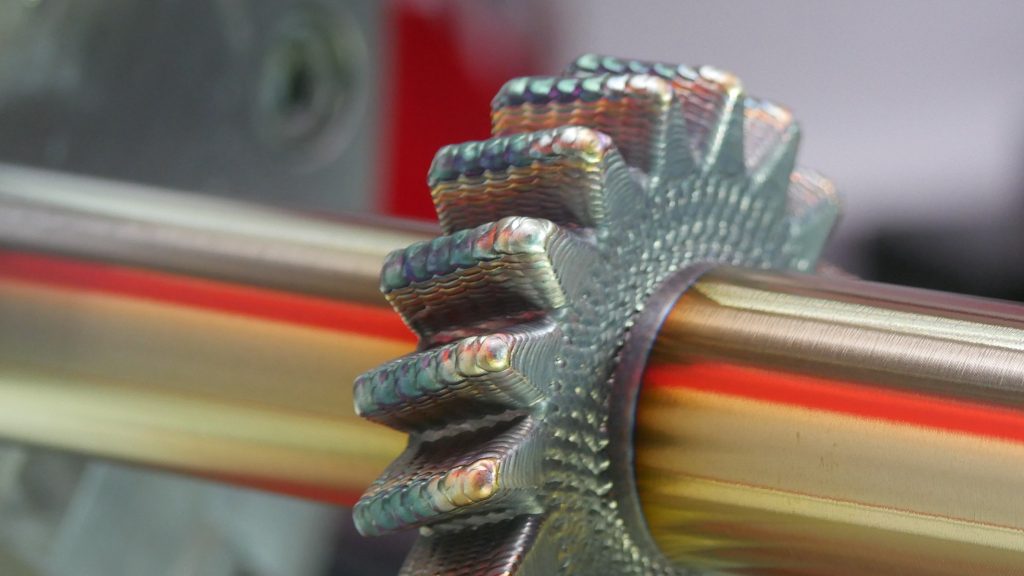

Manufacture, cladding or repair

Additive manufacturing

Additive manufacturing is a manufacturing process in which material is applied layer by layer to create a three-dimensional component.

Advantages of additive manufacturing:

![]() Flexibility

Flexibility

Additive manufacturing can be used to produce almost infinitely complex geometries.

![]() Individualization

Individualization

The creation of individualized components is easy to implement and can be quickly adapted to specific requirements.

![]() Cost savings

Cost savings

Significantly lower material consumption and more efficient production times noticeably minimize costs compared to conventional processes.

![]() Sustainability

Sustainability

With the additive manufacturing process, only the material that is required for component production is used.

Areas of application:

Additive manufacturing is a process of the future and offers many new development opportunities. Additive manufacturing is used as a cost-effective repair solution for defective components or for the production of new components in individual or series production:

![]() Industry and agriculture

Industry and agriculture

![]() Automotive, railroad and shipbuilding

Automotive, railroad and shipbuilding

![]() Machine, tool and mold making

Machine, tool and mold making

![]() Oil and gas industry, mining

Oil and gas industry, mining

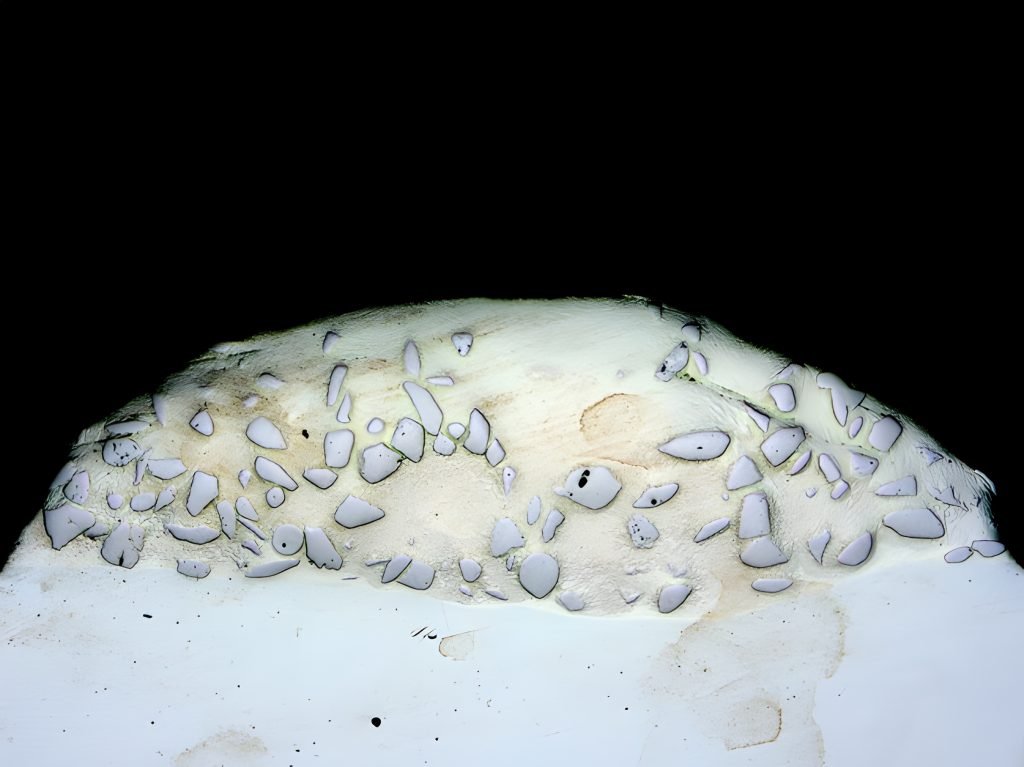

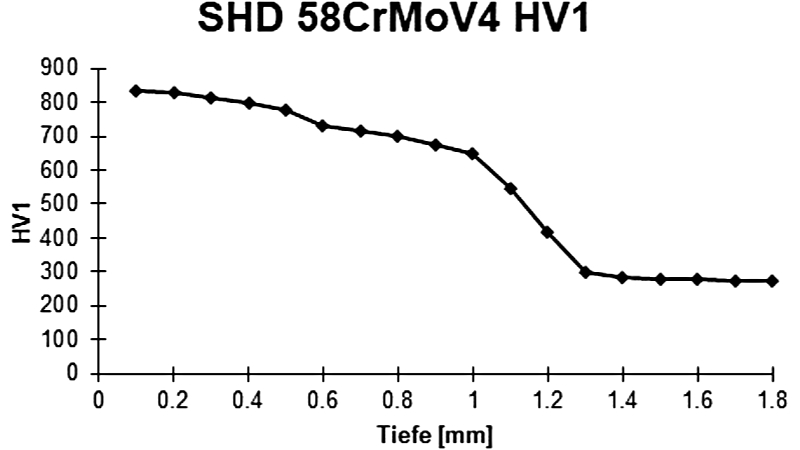

Process and quality assurance

Sample production and verification

With our in-house metallography, we support the development of your process and thus ensure the best possible quality and the most efficient process.

Use the option of sample fabrication in the run-up to production to ensure optimum results on the components to be machined.

We offer the following test procedures in our metallography department:

![]() Manufacture of macrosections

Manufacture of macrosections

![]() Crack testing (penetration testing)

Crack testing (penetration testing)

![]() Hardness measurement (Vickers HV0.1 – HV1; UCI HV5)

Hardness measurement (Vickers HV0.1 – HV1; UCI HV5)

![]() Hardness depth profile measurement

Hardness depth profile measurement

Our machinery

Laser systems for your components

We offer contract manufacturing on 3 reliable laser systems. A fourth system is currently being developed and is expected to be available for your components in mid-2024 with the highlights “internal laser cladding” and “CMT welding”.

With our mobile laser system, we can also process large components on your premises.

System P298

ALOhybrid

System P264

ALOstation

System P240

ALOstation

System P227

ALOstation

Your contact partners

We are here for you!

Contract manufacturing

Laser hardening

Nadja Wolf

Customer consultant

Phone: +49 (0) 35 204 79 44 0

Fax: +49 (0) 35 204 79 44 1

E-Mail: anfragen@alotec.de

Contract manufacturing

Laser cladding

Dipl.-Ing. Lukas Olawsky

Development engineer

Phone: +49 (0) 35 204 79 44 19

Fax: +49 (0) 35 204 79 44 1

E-Mail: anfragen@alotec.de

Customer service

Technical sales

Dipl.-Ing. Marian Ullrich

Sales Manager

Phone: +49 (0) 35 204 79 44 20

Mobil: +49 (0) 15 20 / 5 25 96 63

E-Mail: marian.ullrich@alotec.de

Want to find out more about us?

Read more.

Informative brochures on technologies and production options are available for download.

Our applications in moving images

Roll it – laser on

Laser hardening

Laser powder cladding

Laser wire cladding