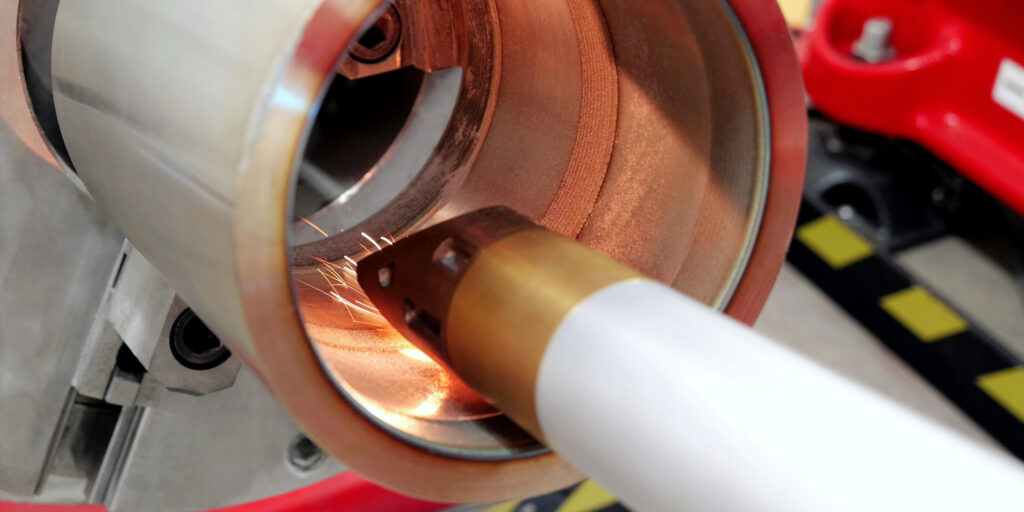

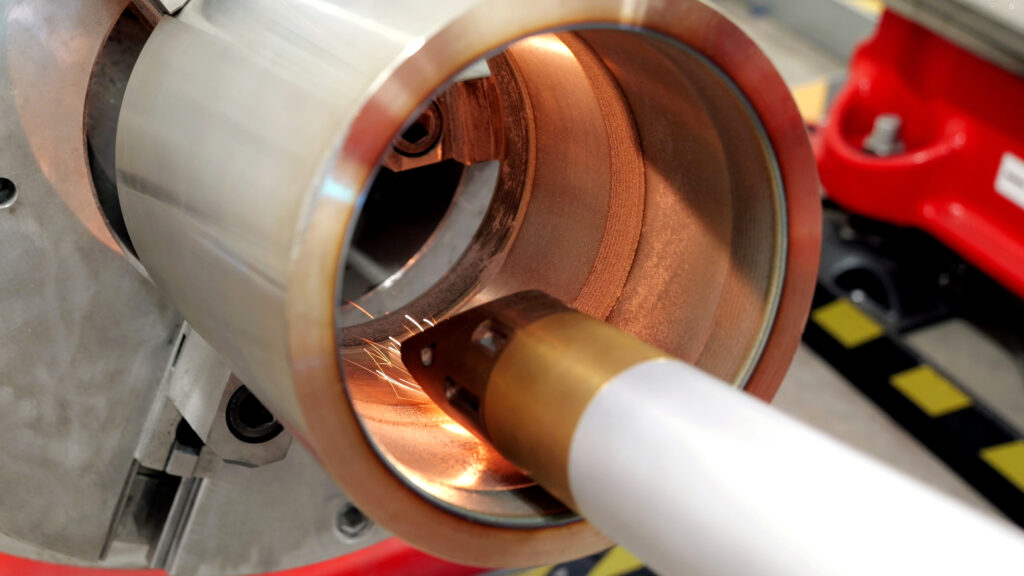

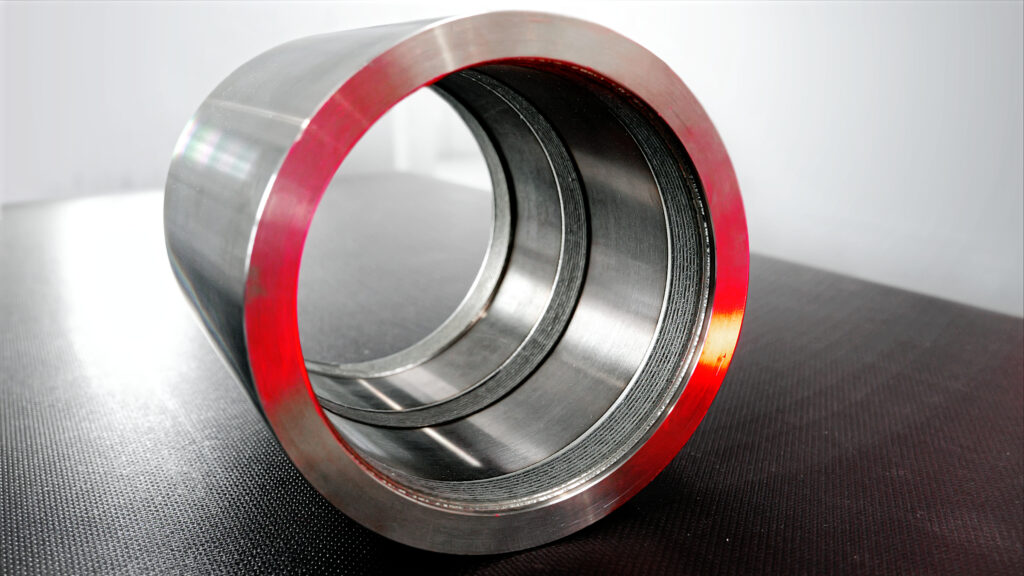

Repair and coating of

internal surfaces

Laser cladding for

Internal surfaces and contours

We offer professional repairs, coatings and design adjustments on hard-to-reach internal surfaces such as internal diameters, internal contours of pipes, internal cylinder surfaces and blind holes. We use our expertise to deliver precise welding results, particularly in engine, machine and tool construction.

With over 20 years of experience in laser cladding and innovative internal coating optics, we achieve outstanding results. The unique 60° inclined nozzle also enables deep blind holes to be processed.

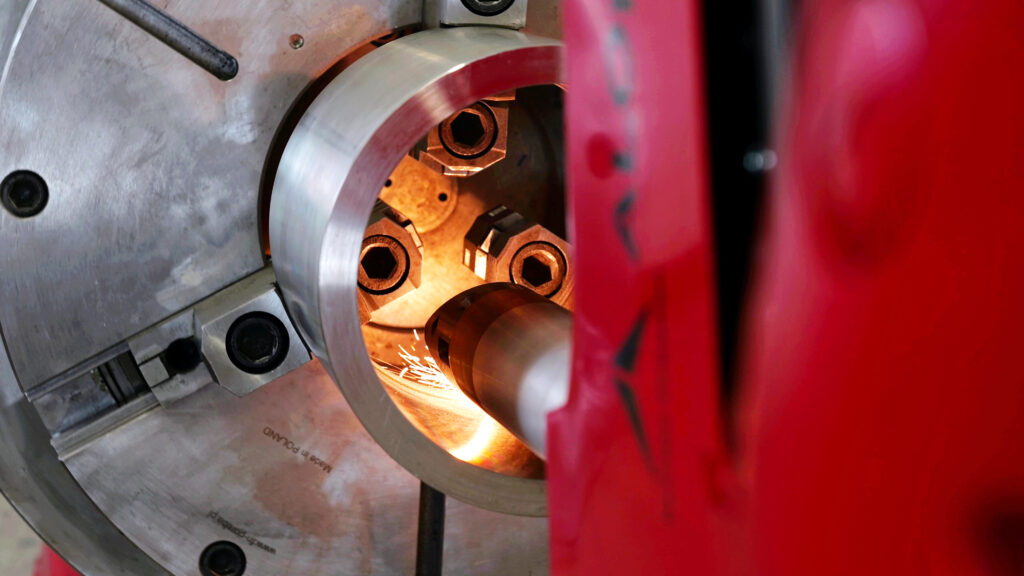

Internal coating optics

ALOpowderID

The ALOpowderID internal coating optic is a modular internal coating unit for laser cladding of complex deep-seated internal contours. The new design is designed for efficient and highly productive internal coating with iron, nickel, copper and cobalt-based alloys. Thanks to the 60° inclined coating nozzle, blind holes can also be processed right to the end.

![]() Technical data:

Technical data:

- Efficient cooling for high laser powers up to 8 kW

- Immersion depth: up to 450 mm / can be extended to 1000 mm

- Diameter: for openings from Ø 70 mm

- Track widths: from 4 to 7 mm

- Integrated sensors for thermal monitoring and control

Wide range of applications

For a wide range of industries

Internal coating offers a wide range of possibilities for different industries: Automotive industry / Mechanical engineering and toolmaking / Oil and gas industry / Power generation / Shipbuilding and offshore industry and especially where high precision, accessibility to hard-to-reach areas and long component life are crucial. It enables not only repairs and coatings, but also the adaptation of components to specific application requirements, resulting in cost savings and increased efficiency.

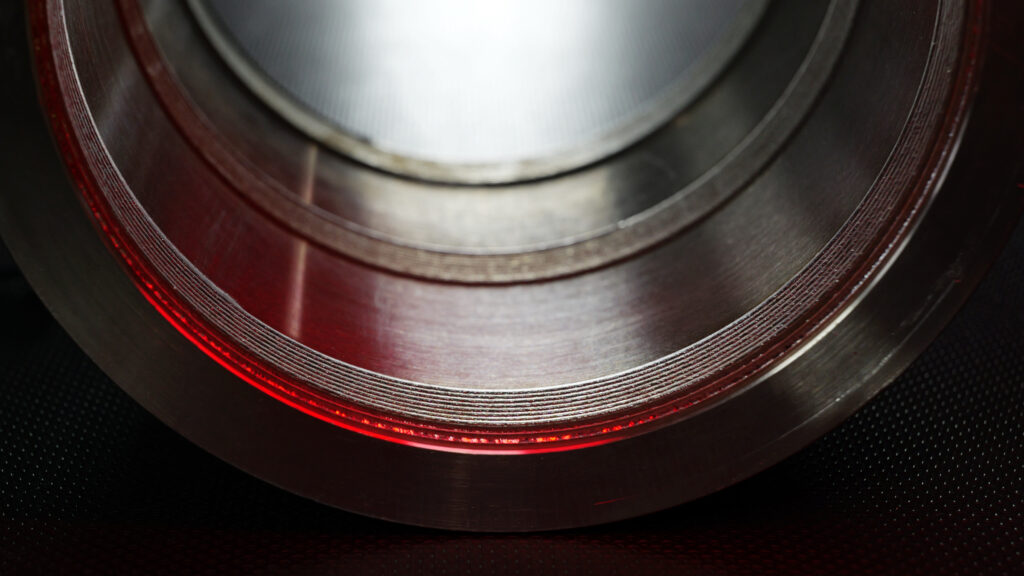

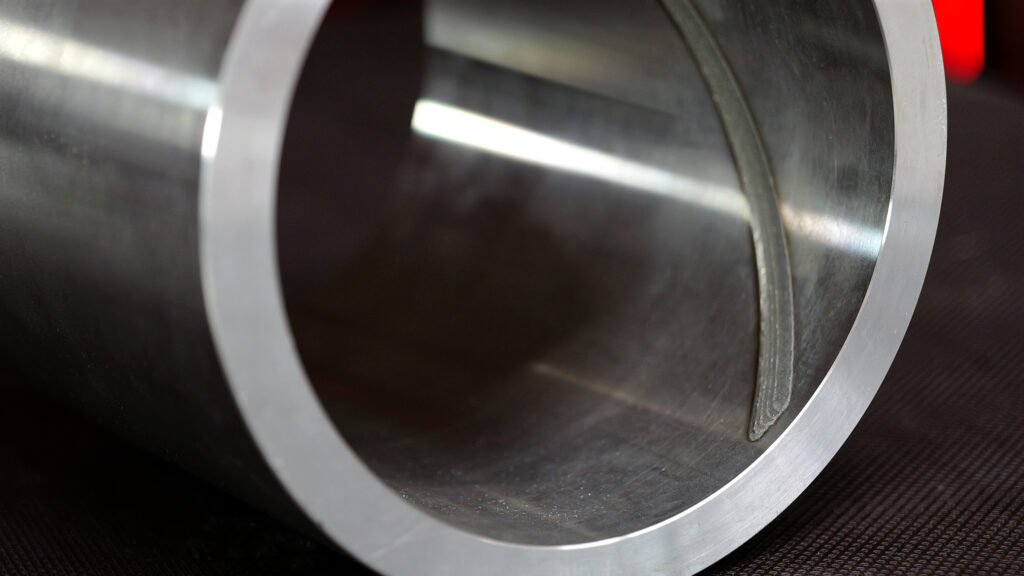

![]() Inner cylinder surface with parallel concentric weld tracks:

Inner cylinder surface with parallel concentric weld tracks:

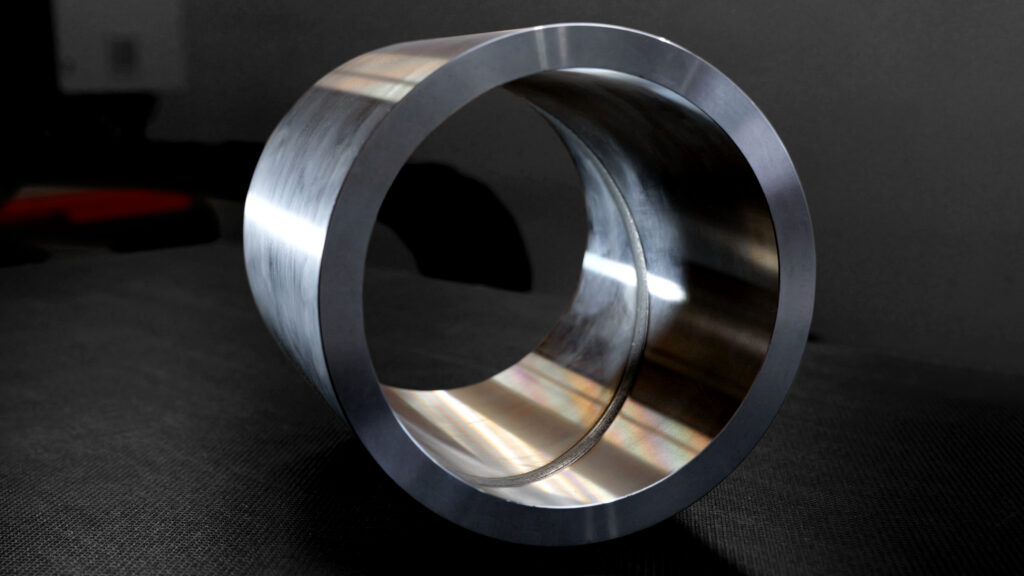

![]() Inner cylinder surface with a welding spiral:

Inner cylinder surface with a welding spiral:

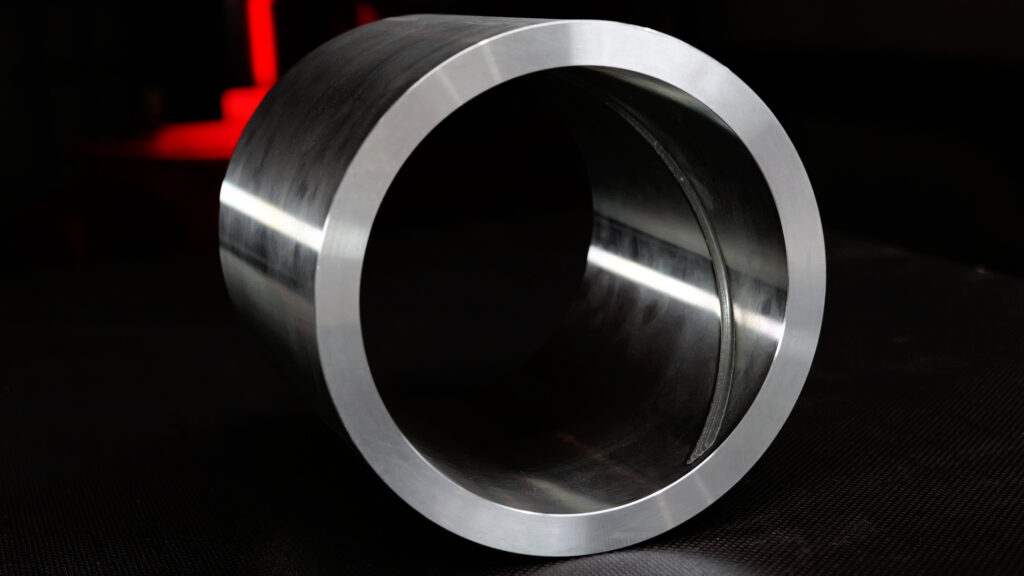

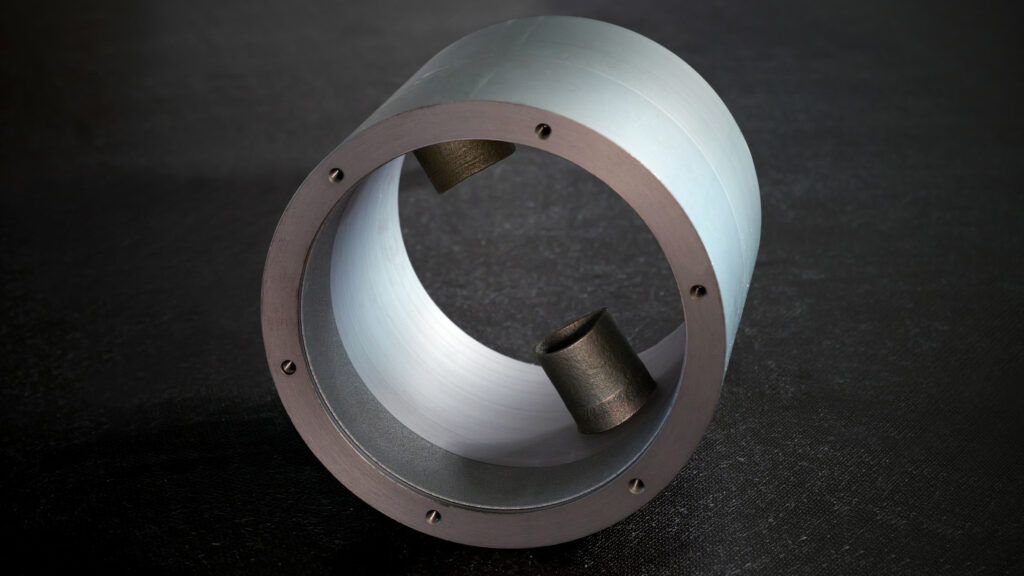

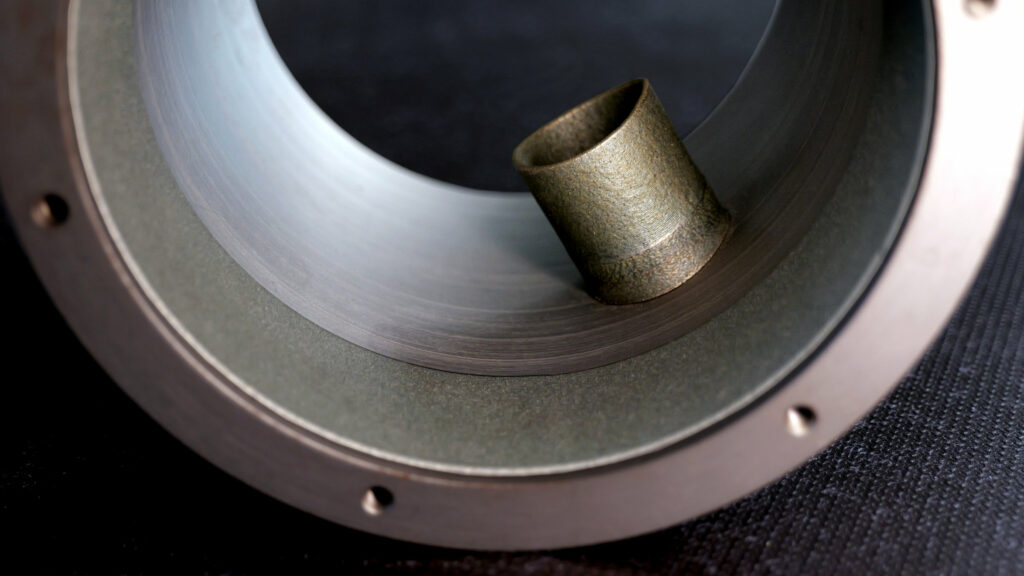

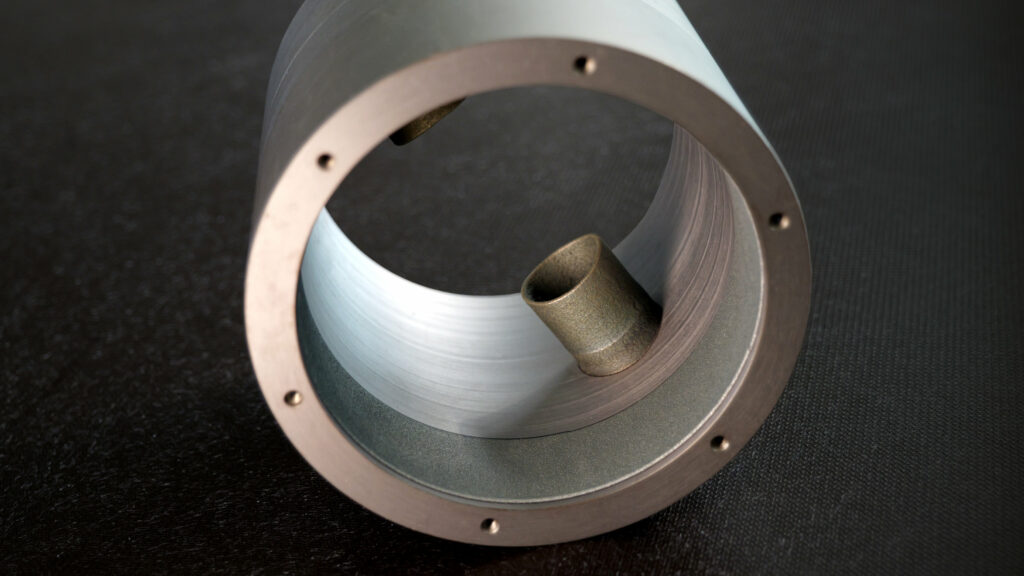

![]() Additive manufacturing of two flanges on the internal surface (with nozzle at 90°):

Additive manufacturing of two flanges on the internal surface (with nozzle at 90°):

![]() Automotive industry

Automotive industry

- Applications: Repair and coating of engine components, gearboxes and other complex components

- Advantages: The ability to machine hard-to-reach internal contours is particularly valuable for the repair of engine blocks, cylinder heads and transmission parts that frequently suffer wear or damage

![]() Machine and tool construction

Machine and tool construction

- Applications: Repair and modification of machine components and coating of tools and molds

- Advantages: The ability to machine internal surfaces makes it possible to extend the service life of expensive and customized machine and tool parts

![]() Oil and gas industry

Oil and gas industry

- Applications: Repair and protection of pipes, valves, pumps and other components used in harsh environments

- Advantages: Protection against corrosion and wear thanks to special coatings, ideal for processing long pipes and drill holes

![]() Energy production

Energy production

- Applications: Maintenance and repair of turbines, generators and other components in power plants

- Advantages: Increased efficiency and service life of systems through precise repairs and coatings, especially in areas exposed to high temperatures and high pressure

![]() Shipbuilding and offshore industry

Shipbuilding and offshore industry

- Applications: Repair and coating of ship drives and other maritime components

- Advantages: Improved protection against corrosion and wear in maritime environments, as well as the ability to work efficiently in hard-to-reach areas

Cladding on internal surfaces in the moving image

Roll it – Laser on

Are you interested?

Let’s talk.

Are you interested in the process of cladding on internal surfaces and need advice?

Please use the following form – we will get back to you as soon as possible.

Want to find out more about internal coating?

Let’s talk.

Request non-binding advice on internal coating now.

Laser cladding in the moving image