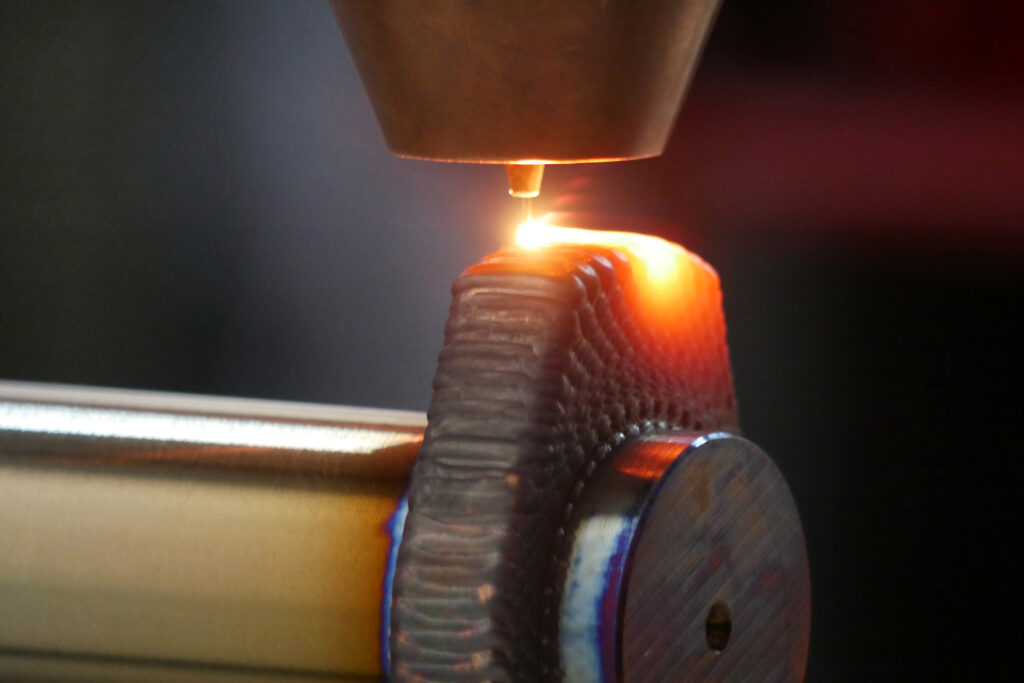

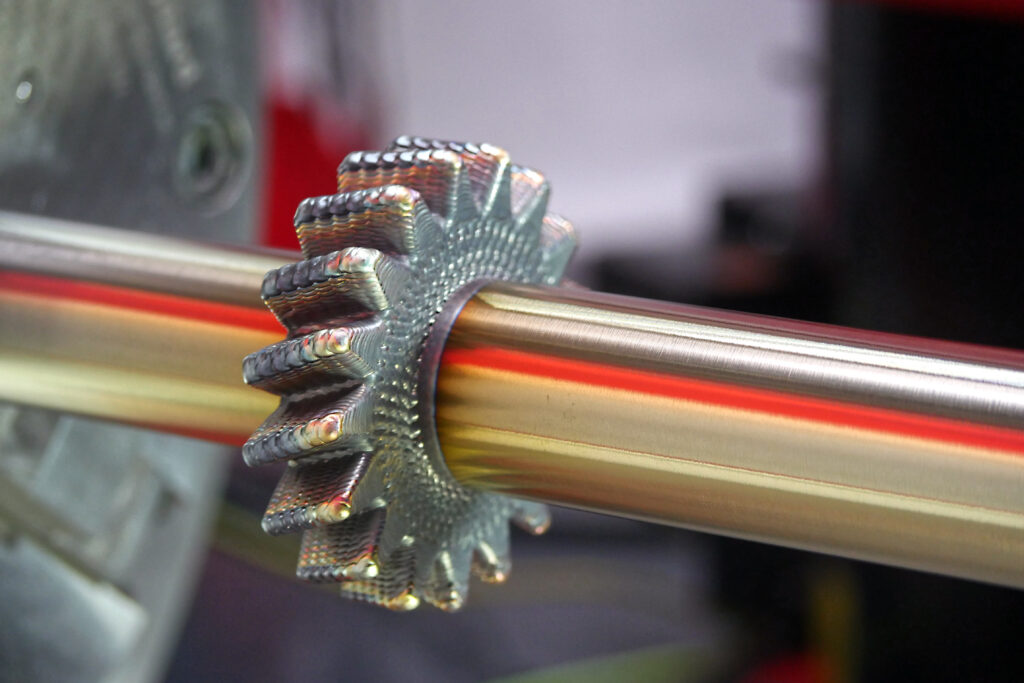

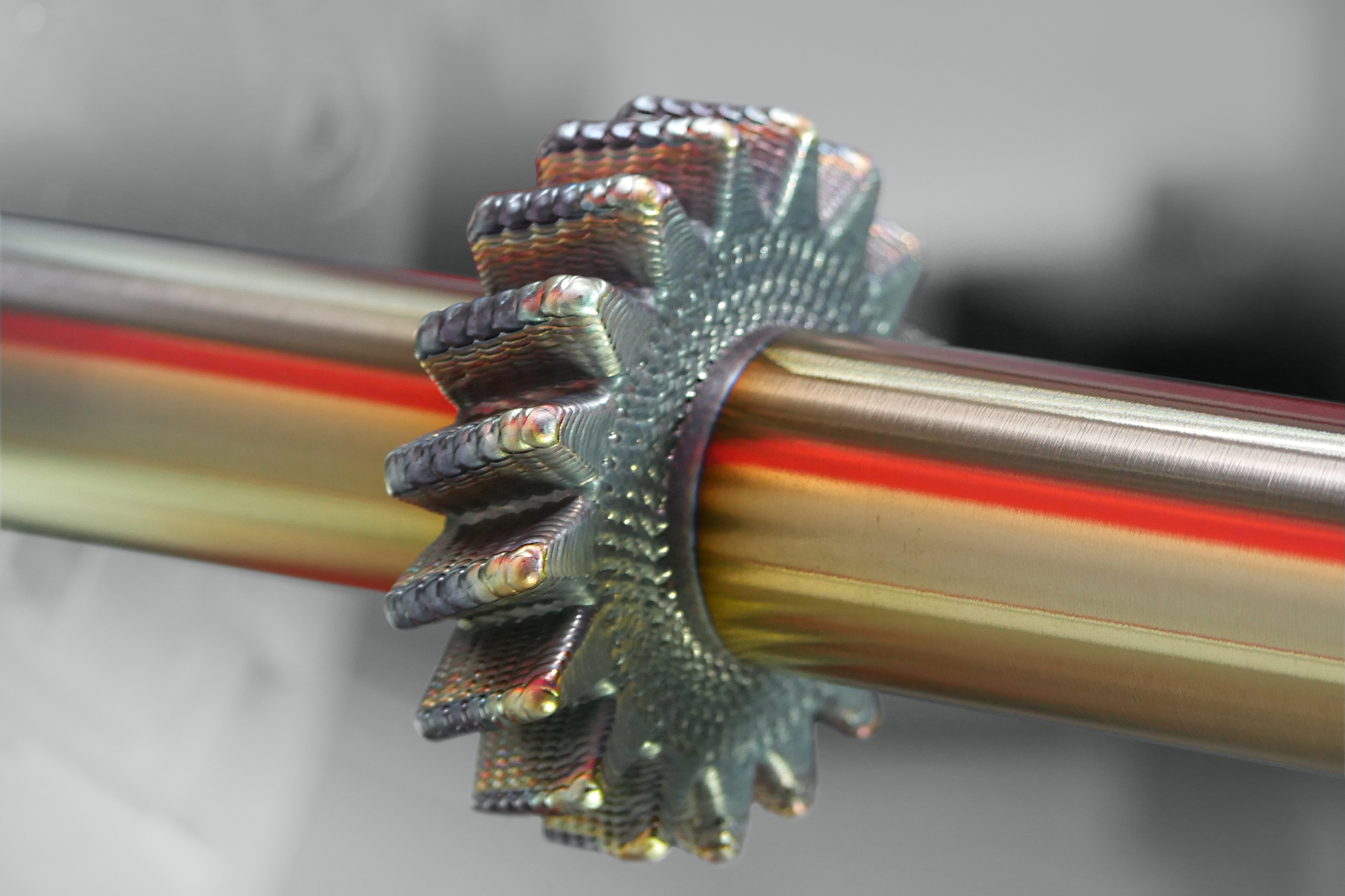

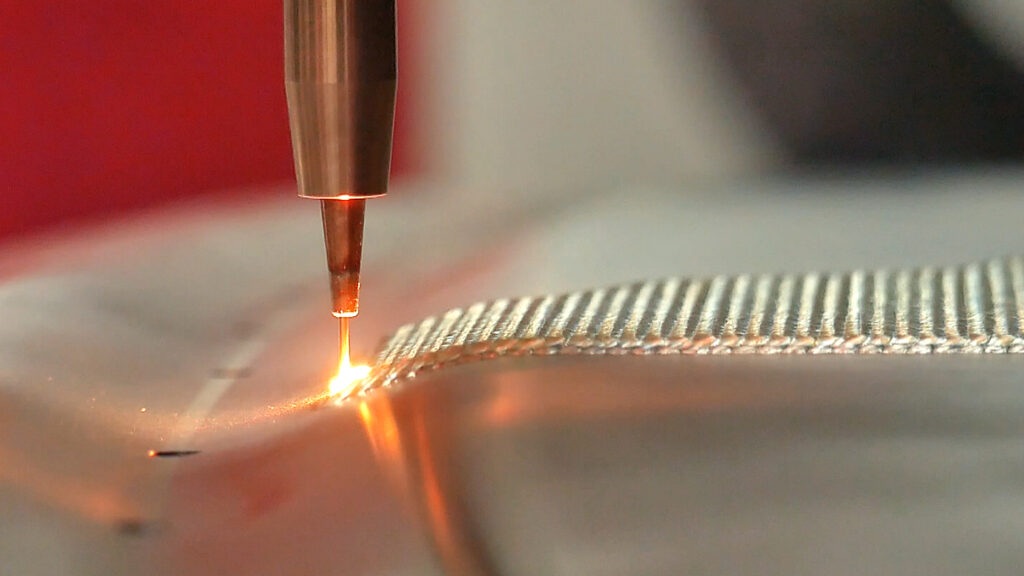

Additive manufacturing of 3D components, using the example of a gear wheel.

Laser wire cladding

ALOwire

ALOwire

Cladding and repair with wire

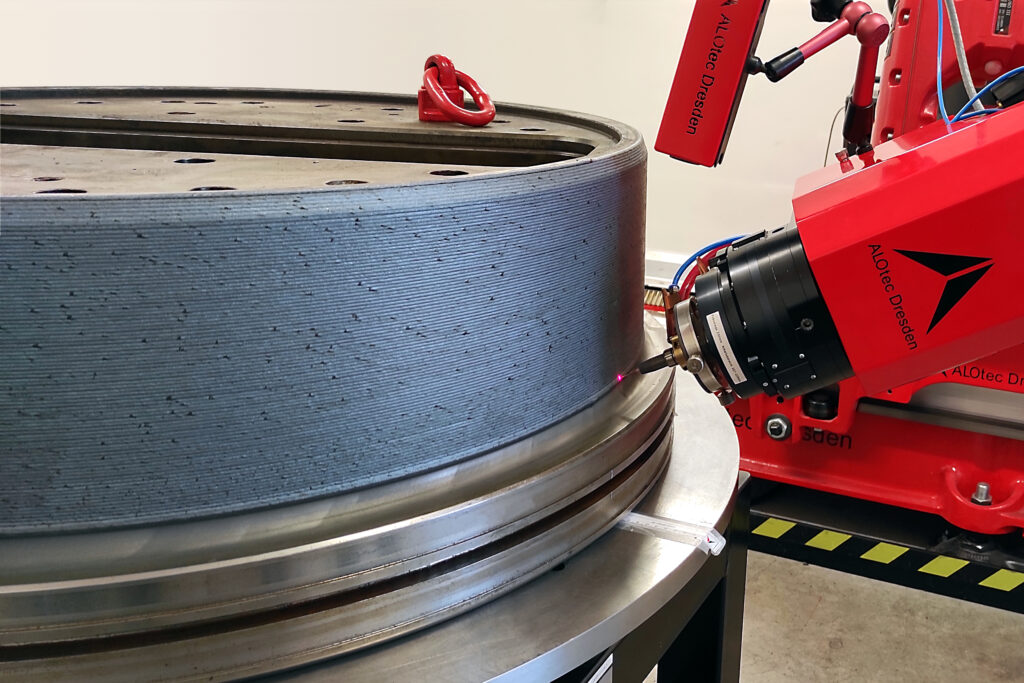

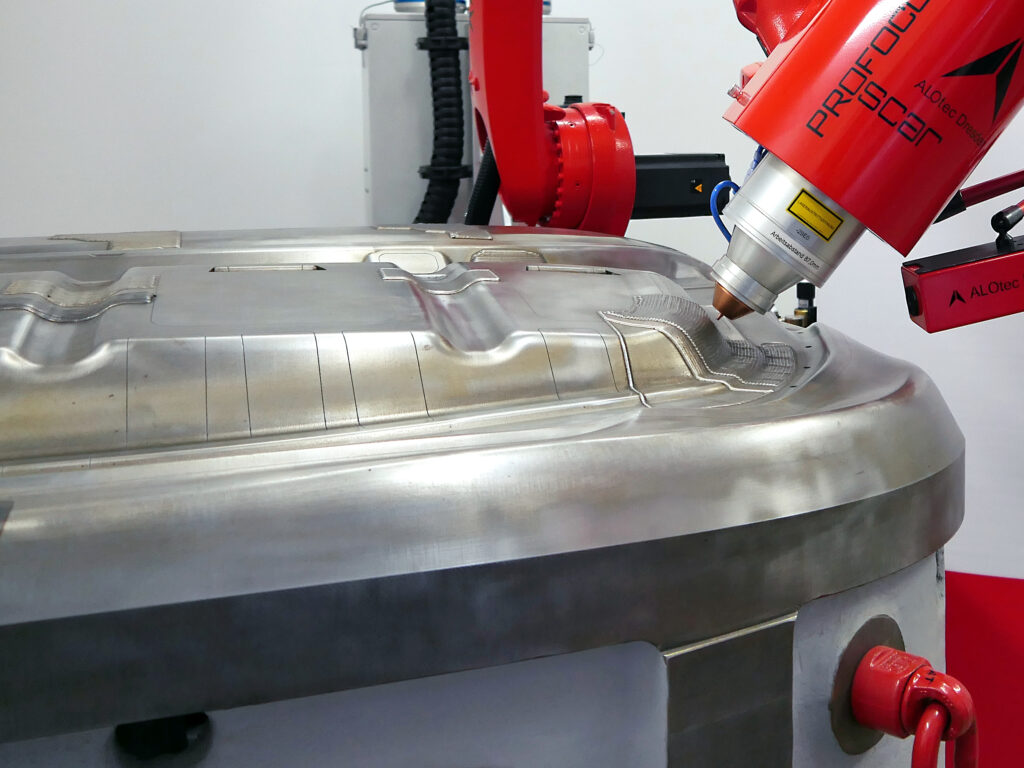

The ALOwire technology for repair, wear protection and additive manufacturing impresses with 100% material utilisation, high productivity, processing of large components, cleanliness of the process and the ability to perform cladding in all welding positions.

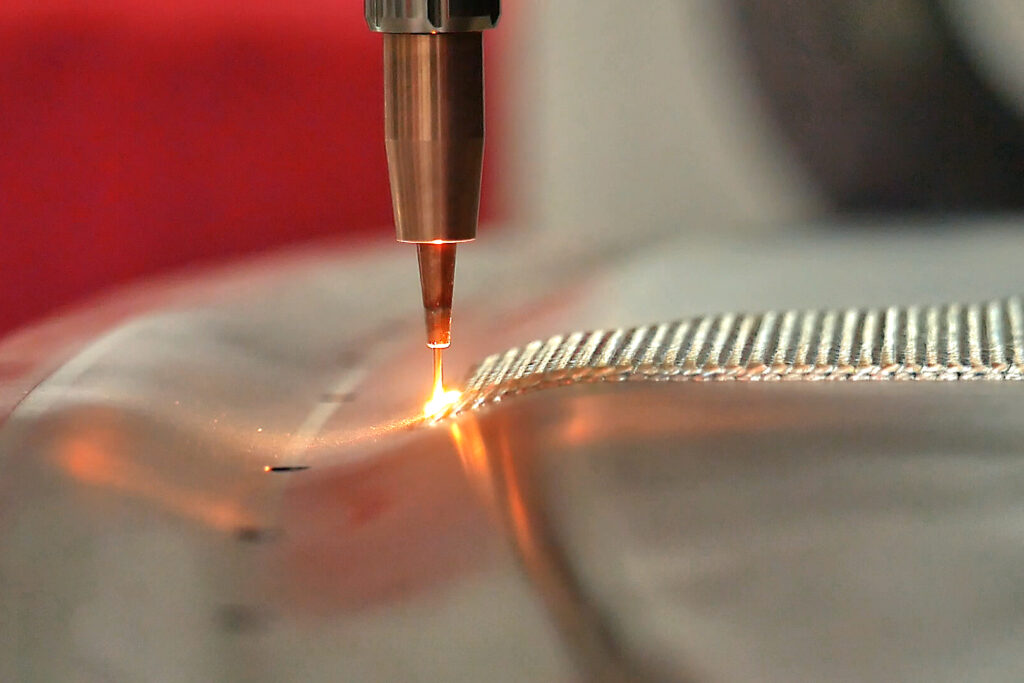

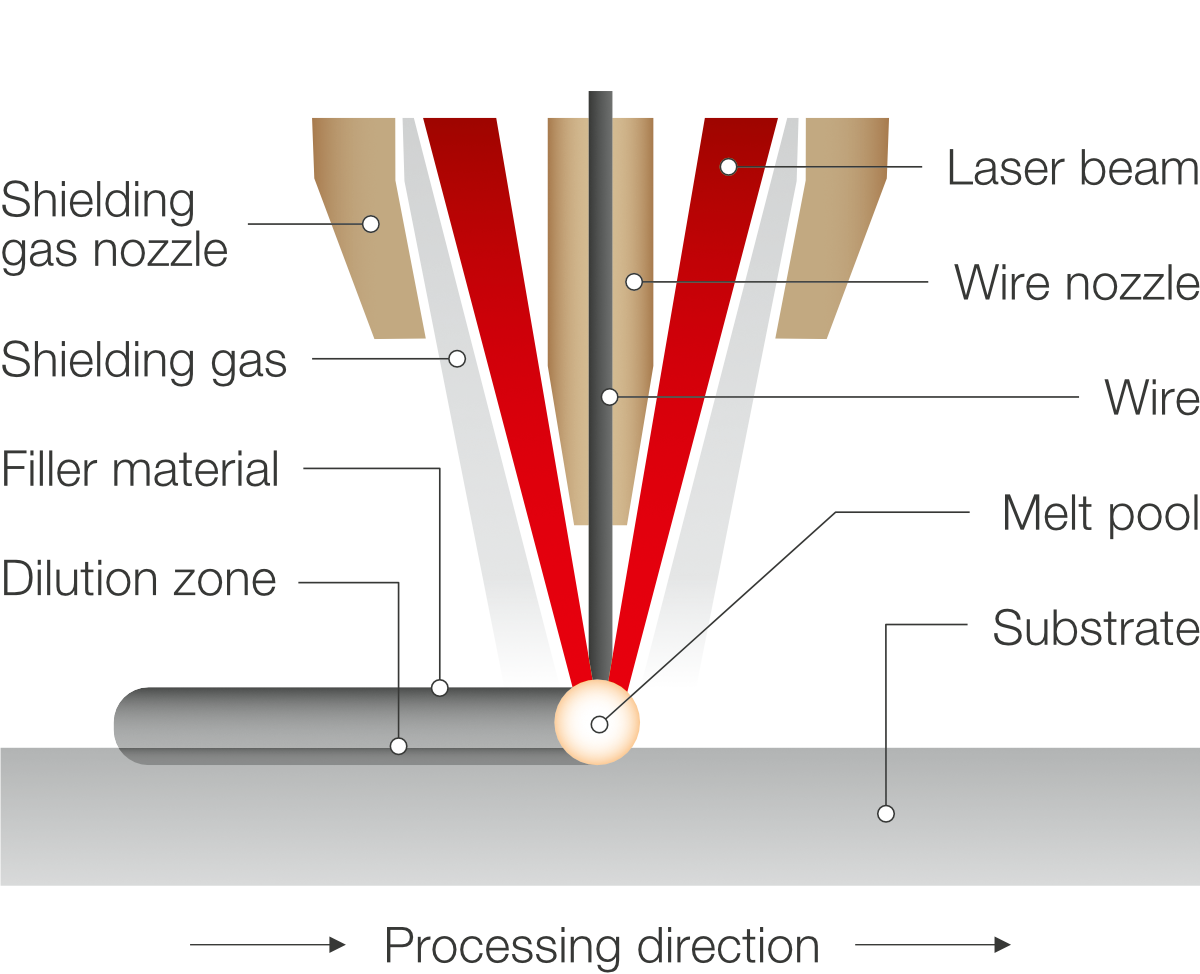

In ALOwire laser wire cladding, the laser beam is split into individual beams using optical elements. These create a localised molten pool on the surface of the base material, into which a wire is fed concentrically.

Due to the lower energy input compared to conventional welding processes, the components experience less distortion and minimal changes in microstructure.

Technology for all shapes

Processing optics

Depending on the function and application of the component, different processing optics ensure optimum surface processing.

ALOwire

Optics for wire cladding

ALOtwin

Two technologies – wire and powder cladding

Ranging from forming tools to cutting tools

Applications with ALOwire

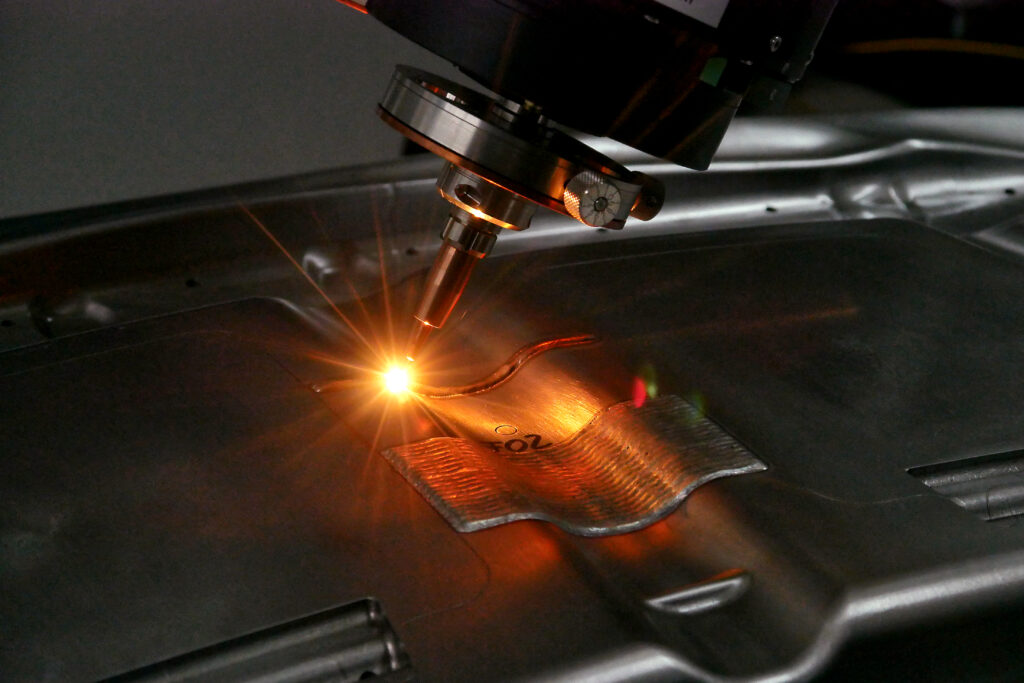

Laser wire cladding is used for the application of wear protection layers on heavily stressed components. Furthermore, it is used for the repair of components or for the simple and fast modification of component geometries in machine, tool and mould industry as well as for the additive manufacturing of 3D components.

Forming dies Rollers and shafts

Cutters & Cutting tools Bearing shells

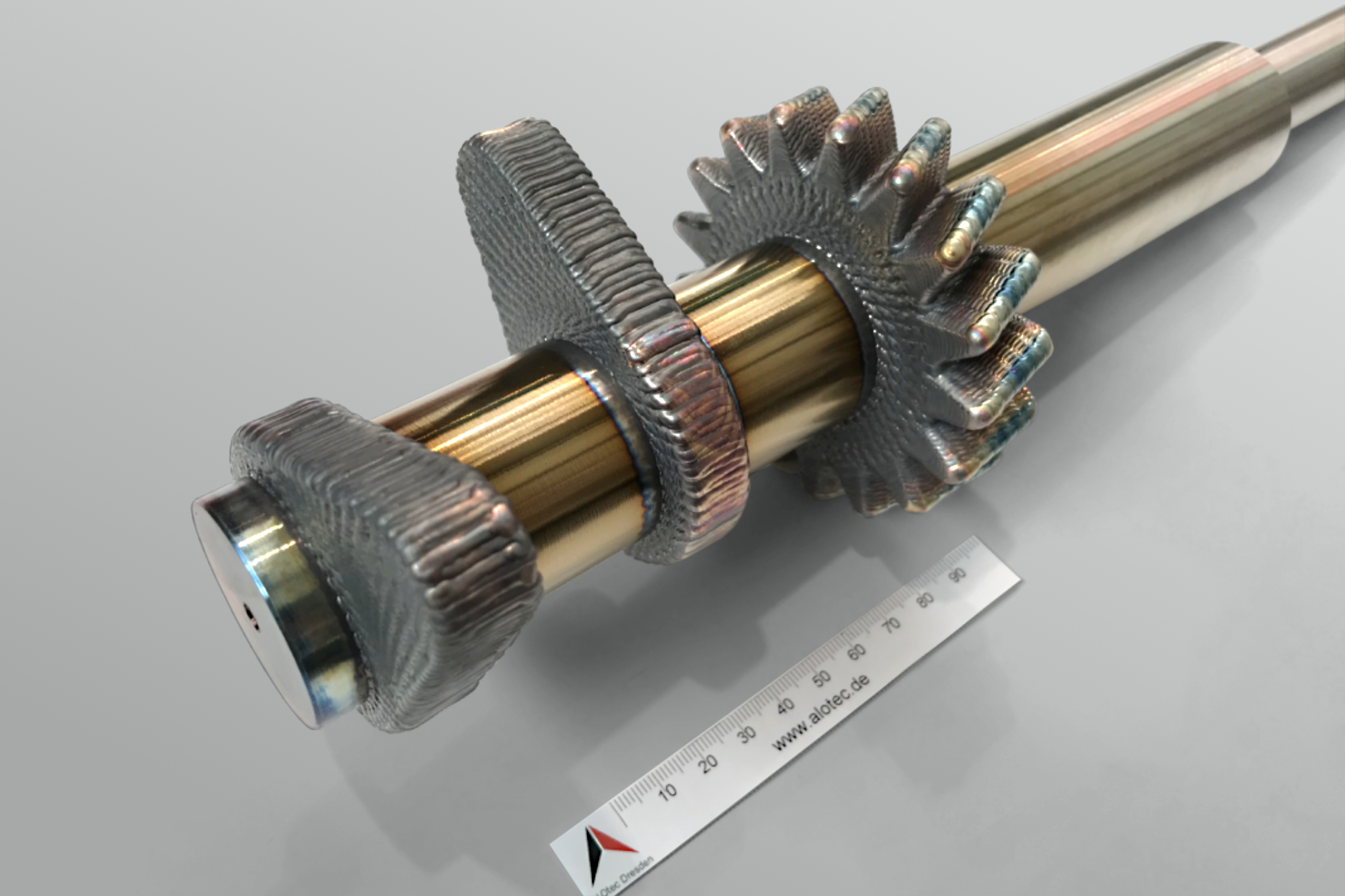

Gear wheels & cams 3D components

ALOwire

Sample components

-

Gear wheel

-

Gear wheel with cam

Additive manufacturing of 3D components, using the example of two cams and a gear wheel.

-

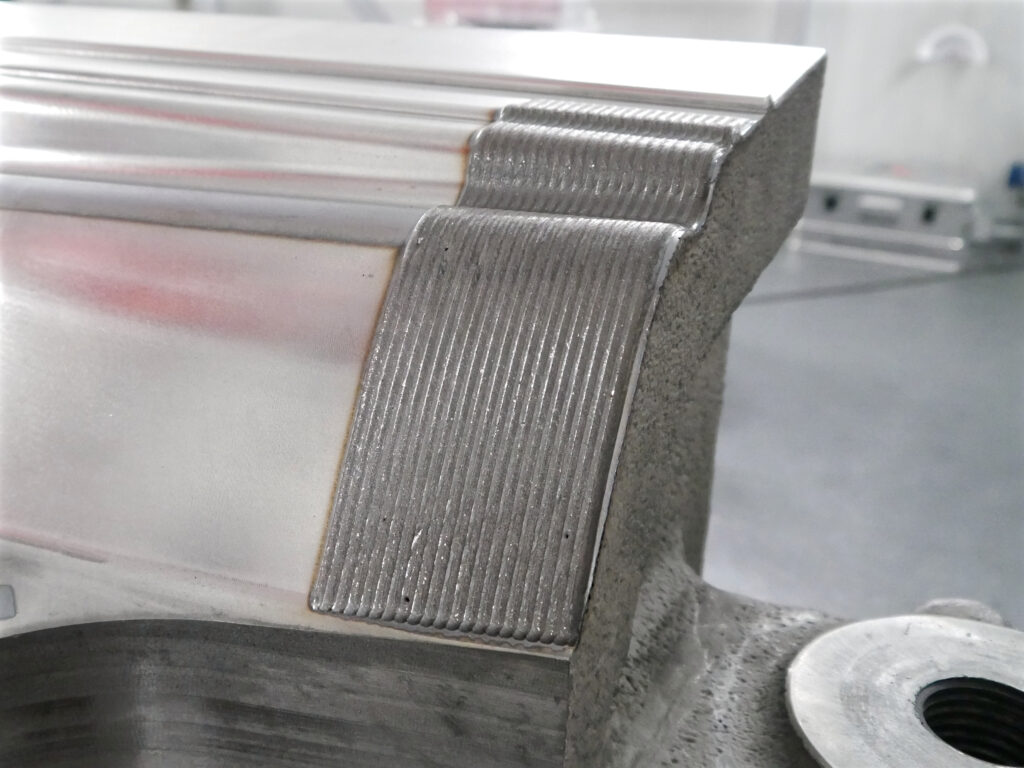

Forming die

Laser cladding with wire on a forming tool.

Laser cladding by wire

Advantages of ALOwire

Quality assurance during the processes

Hardness up to 66 HRC

Minimal distortion due to small heat input

Direction-independent process control

Energy efficient and environmentally friendly

Optimum filler materials

Deposition rate up to 1.5 kg/h

User-friendly due to high working safety

Small batches and single pieces

Ready for all applications

Wire materials

Different types of laser cladding wires – including nickel-based, copper-based and iron-based alloys – ensure optimal cladding according to the desired requirements, such as wear resistance, corrosion resistance and temperature resistance.

- High toughness

- High corrosion resistance

- Ideal as buffer and filler material

- Flexible and economical

- Hardness up to 65 HRC

- Wear resistance due to W, V

- High corrosion resistance due to Cr, Ni

- Good sliding properties

- High corrosion resistance

- High resistance to cavitation

- Good sliding properties

- High corrosion resistance

We’ll find a good bond with you.

Let’s talk.

Whether it’s corrosion and wear protection, repairs, design changes or additive manufacturing of 3D components – our employees will help you find the right solution for your needs.

ALOwire in moving images