Content category.php

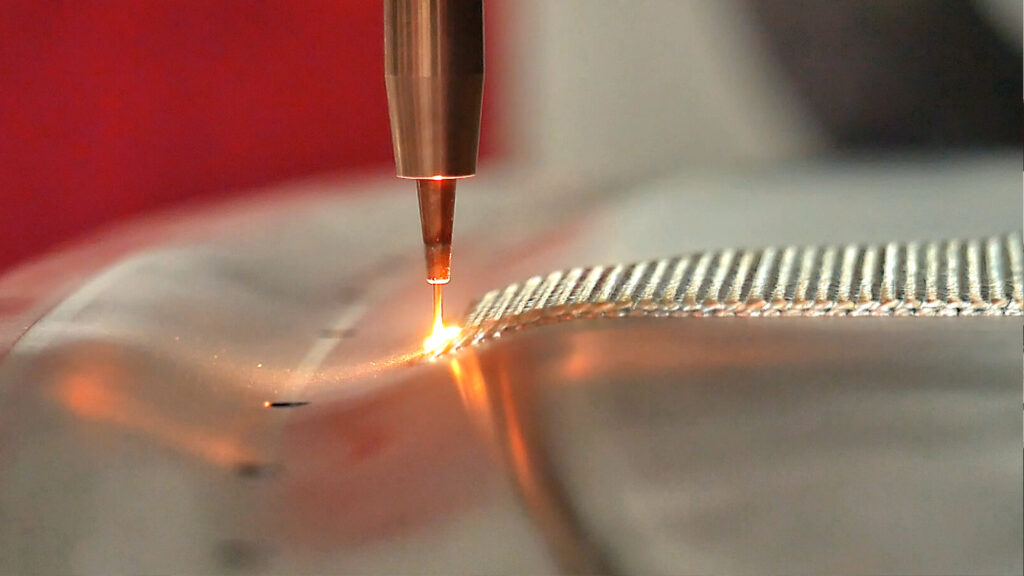

Development of innovative wire-shaped welding consumables and implementation in the laser cladding process of special cast iron alloys.

The aim of the R&D project is to develop a new welding filler material as well as a corresponding system technology and welding process for the sustainable laser cladding of cast iron with spheroidal graphite. The cladding layers should meet application-specific requirements such as hardness, wear resistance and freedom from cracks. This requires interdisciplinary cooperation between industry and research partners in order to ensure a continuous development chain from alloy development to material validation. A central goal is the development of a wire material with an adapted alloy design that offers both good formability and the desired properties for cladding.

Project partners

ALOtec Dresden GmbH

Process technology

quada V+F Laserschweißdraht GmbH

Wire production

Technische Universität Chemnitz

Simulation

Leibnitz-Institut für Festkörper- und Werkstoffforschung Dresden e.V.

Alloy design

Funding of the project

The project “Development of innovative wire-shaped welding consumables and implementation in the laser cladding process of special cast iron alloys (RepCast)” is funded by the Federal Ministry for Economic Affairs and Climate Action.

Funding reference number: 16KN104821

Want to find out more about our research?

Let’s talk.

Whether you have questions about our research and development projects or simply want to share your experiences – we look forward to hearing from you.