Maintenance of a laser system and new processing optics

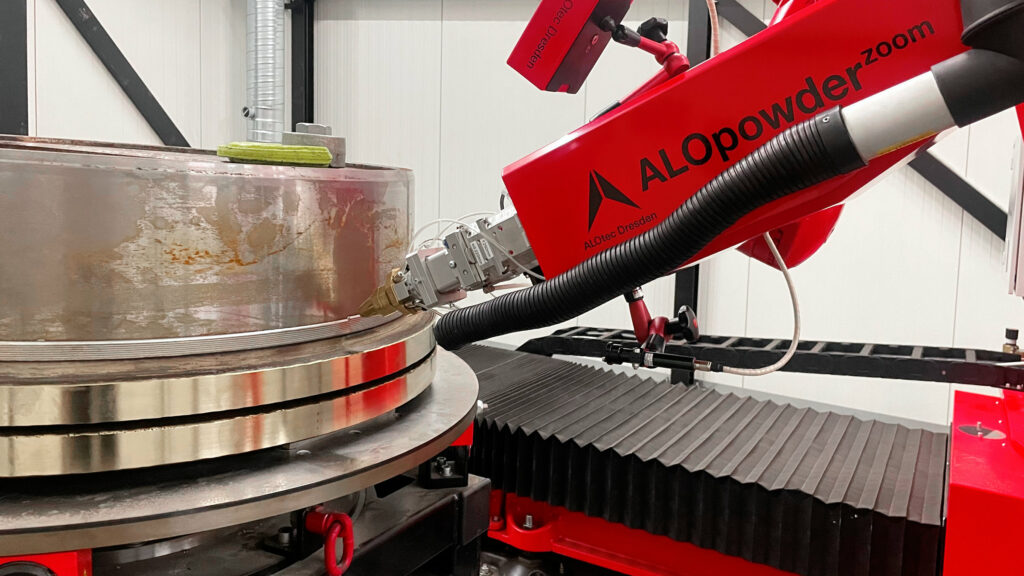

For one of our customers, a leading specialist for mechanical transmission components in Belgium, we recently installed a new ALOpowderzoom processing optic and serviced the laser system.

The ALOpowderzoom is a state-of-the-art zoom optic for laser powder cladding, which is characterized by an 8-beam nozzle, variable laser track widths and maximum flexibility.

Your area of application?

Corrosion and wear protection, repair, design modifications and additive manufacturing – especially for large components such as shafts and bearing shells.

![]() In addition to the installation, we carried out the following maintenance work:

In addition to the installation, we carried out the following maintenance work:

- Inspection and maintenance of the robot system

- Cleaning the cooling systems and fans

- Replacing the extraction system filters

- Software updates for offline programming and the new zoom optics

Through regular maintenance intervals, we ensure that the quality of our laser machining processes remains consistently high and expensive downtimes are avoided. This means that our know-how is continuously incorporated into the optimization of customer systems.

Would you like to find out more about our systems engineering for laser hardening, laser cladding and additive manufacturing? We look forward to providing you with comprehensive advice.