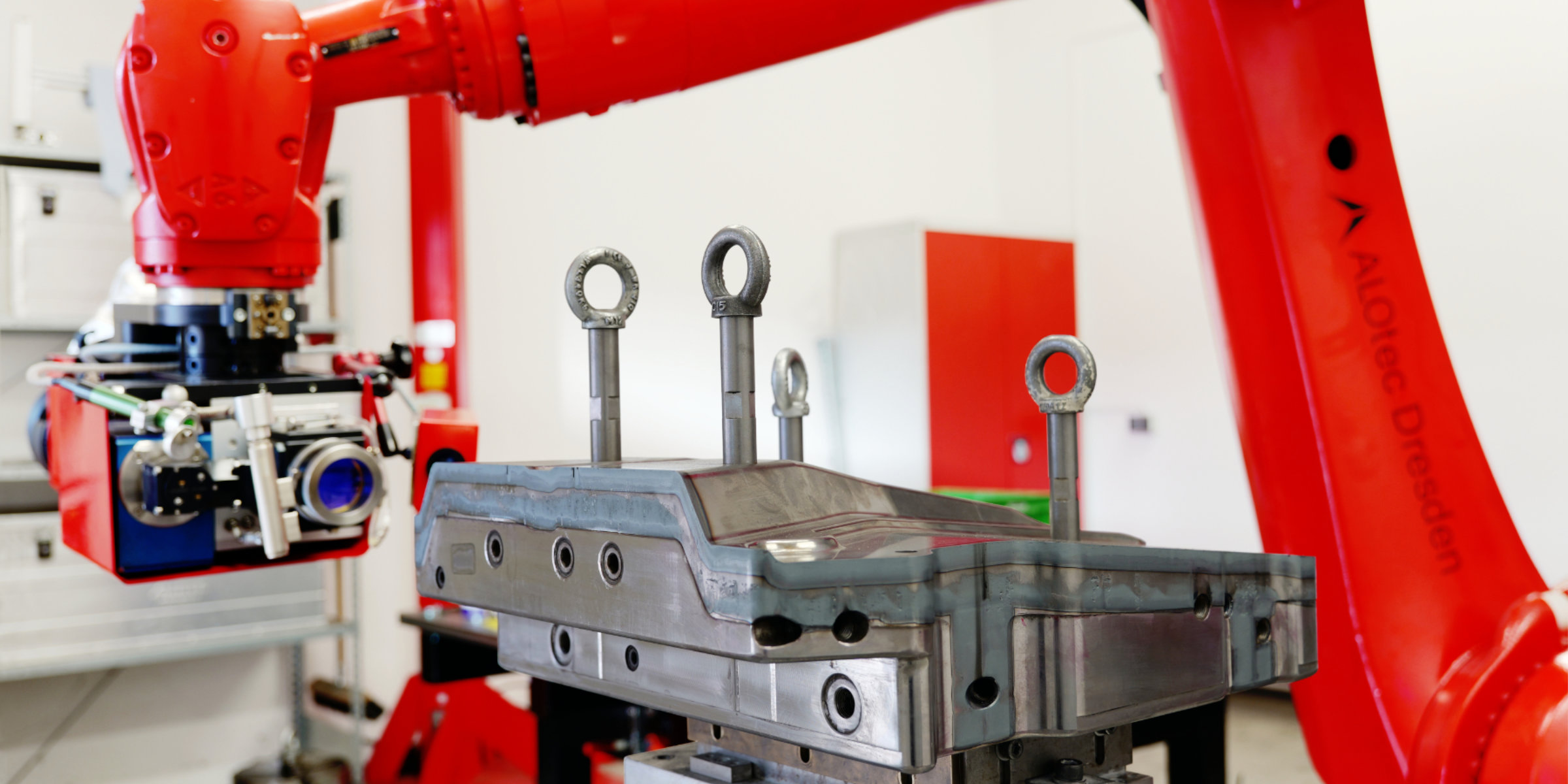

ALOtec Dresden GmbH was spun off from the Fraunhofer IWS in 1998.

System engineering and laser processing

ALOtec Dresden

ALOtec Dresden

About ALOtec Dresden

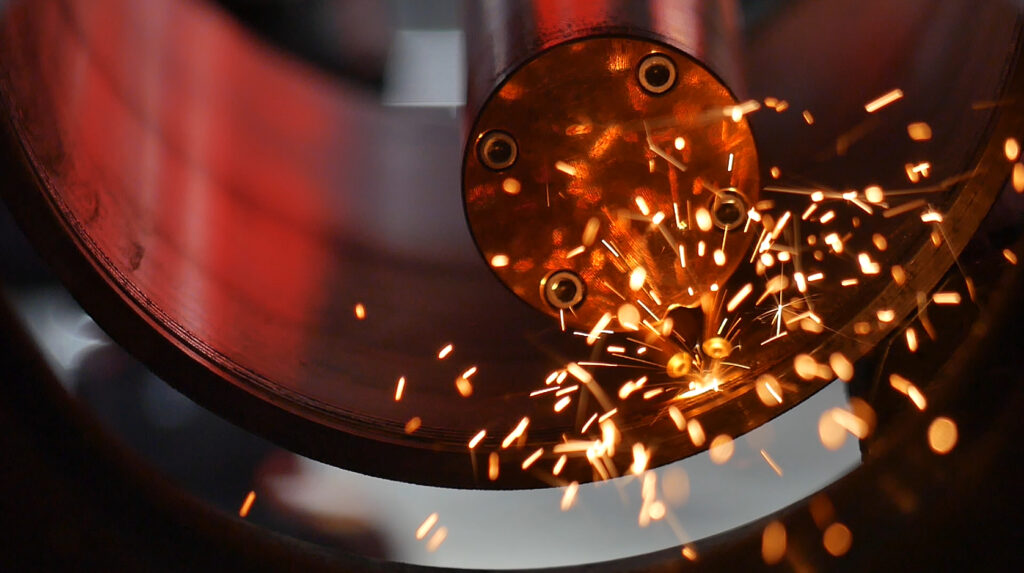

Over 25 years of experience in the field of laser material processing guarantees you the highest quality. We design and manufacture your individual laser system for hardening or cladding and are at your side as a competent service provider in the fields of laser hardening and laser cladding.

In cooperation with the Fraunhofer Institute for Material and Beam Technology in Dresden, we are constantly developing our systems further. You receive a high-tech product “Made in Germany“. We advise you on technology issues and support you in optimizing your technological processes. We are here for you!

Research partners and memberships

Strong together

Dresden University of Technology

Dresden University of Technology is one of the largest technical universities in Germany and one of the leading and most dynamic universities.

VE.MAS innovative

The Saxony Mechanical Engineering Innovation Network VEMASinnovativ serves as a technology and product-open platform for the cross-industry exchange of experience and technology transfer, market expansion and the development of synergies for the further development of production along the entire value chain.

wirePrint

The aim of the WirePrint network is to open up new areas of application for 3D wire printing and to increase the range of industrial applications for the technologies.

AWT

The AWT is a research association of the Industrial Collective Research (IGF) with a strong network consisting of 300 company and association members and 550 individual members.

Our milestones

ALOtec history

-

1998

-

2000

Delivery of a CNC system for laser hardening with diode laser to the company Christoph Liebers GmbH & Co. KG.

-

2002

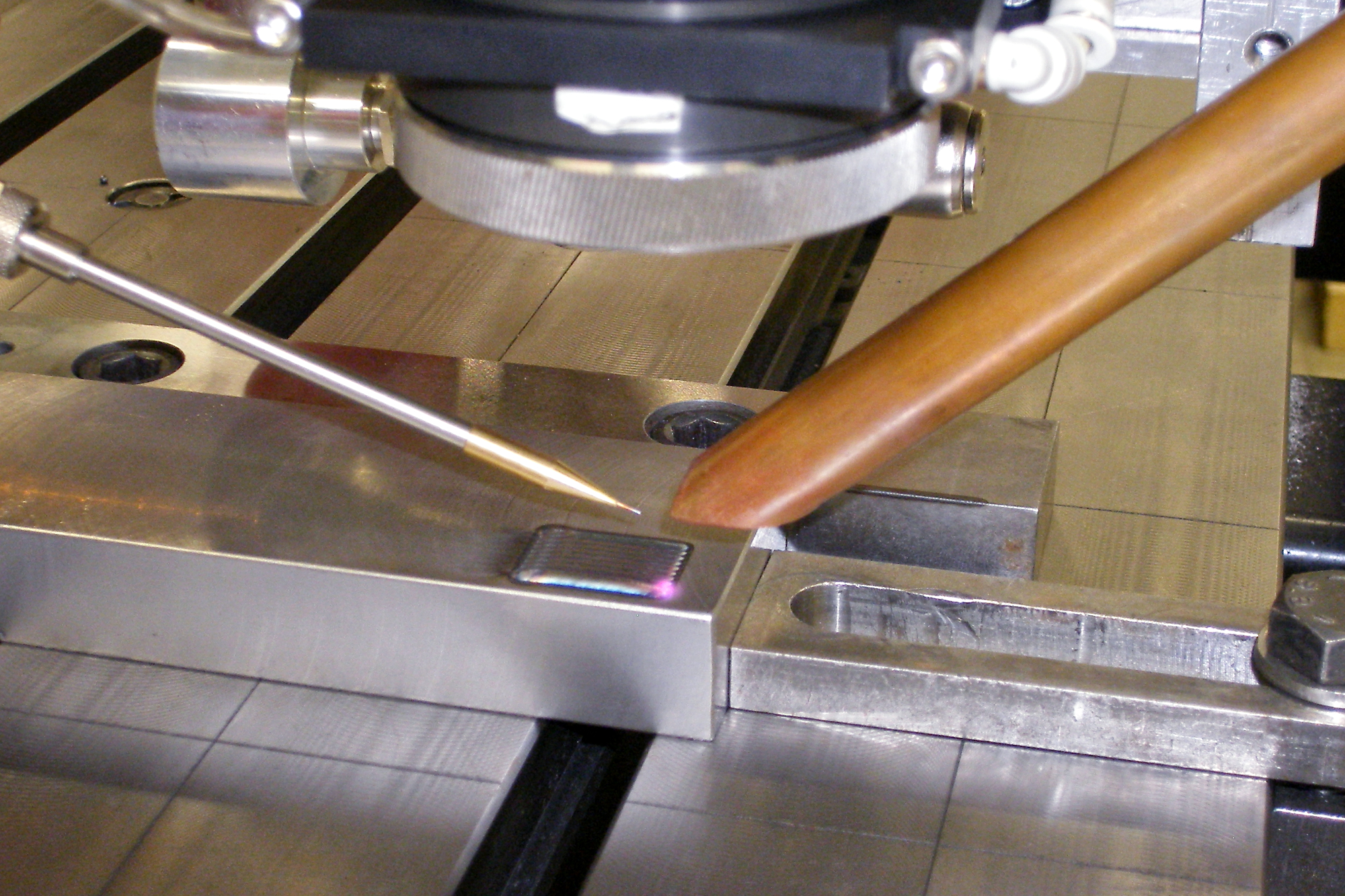

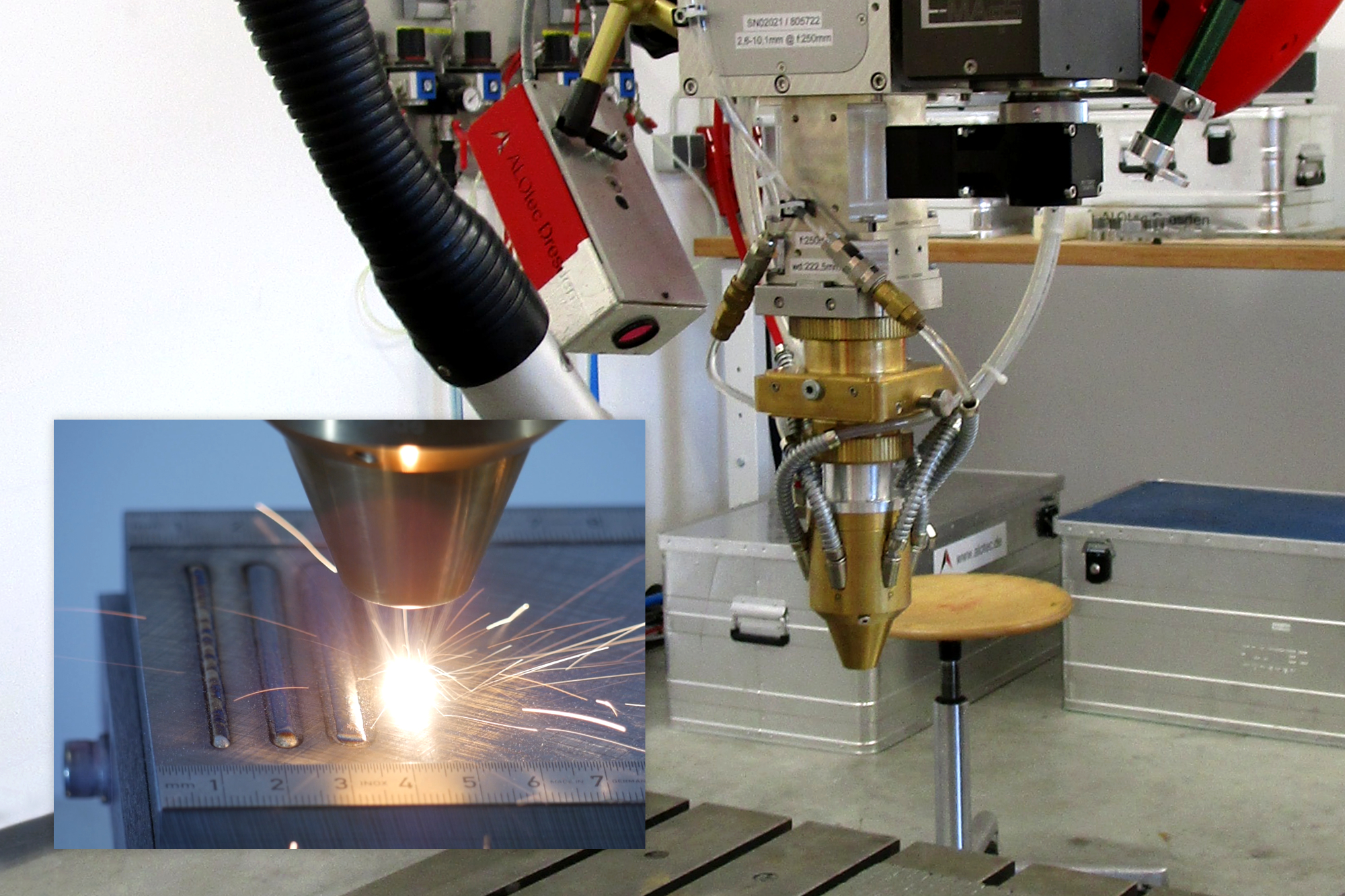

Entry into contract work with hardening and welding on a 4-axis CNC system and a 2 kW diode laser with spot sizes from 5 to 16 mm.

-

2004

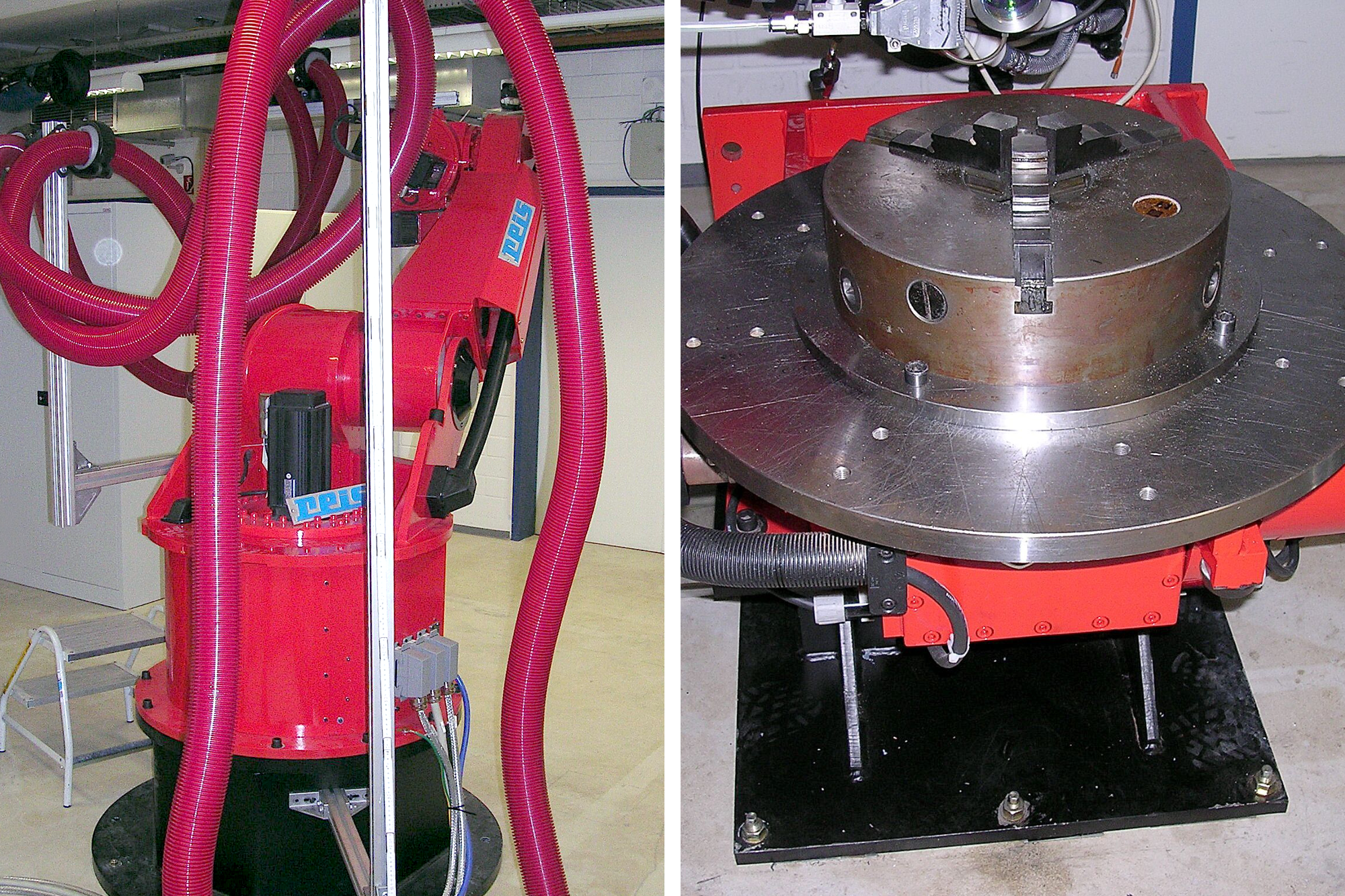

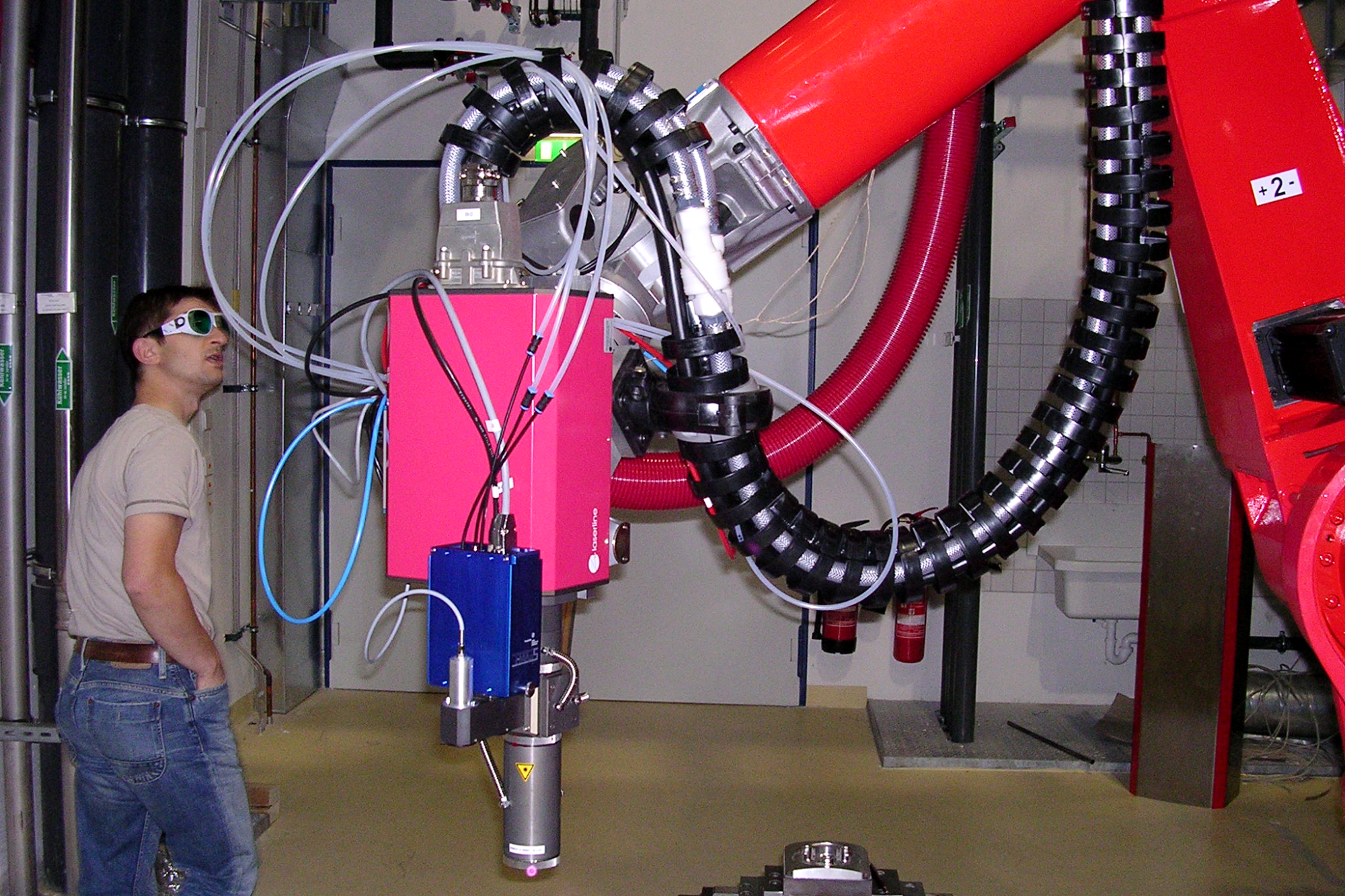

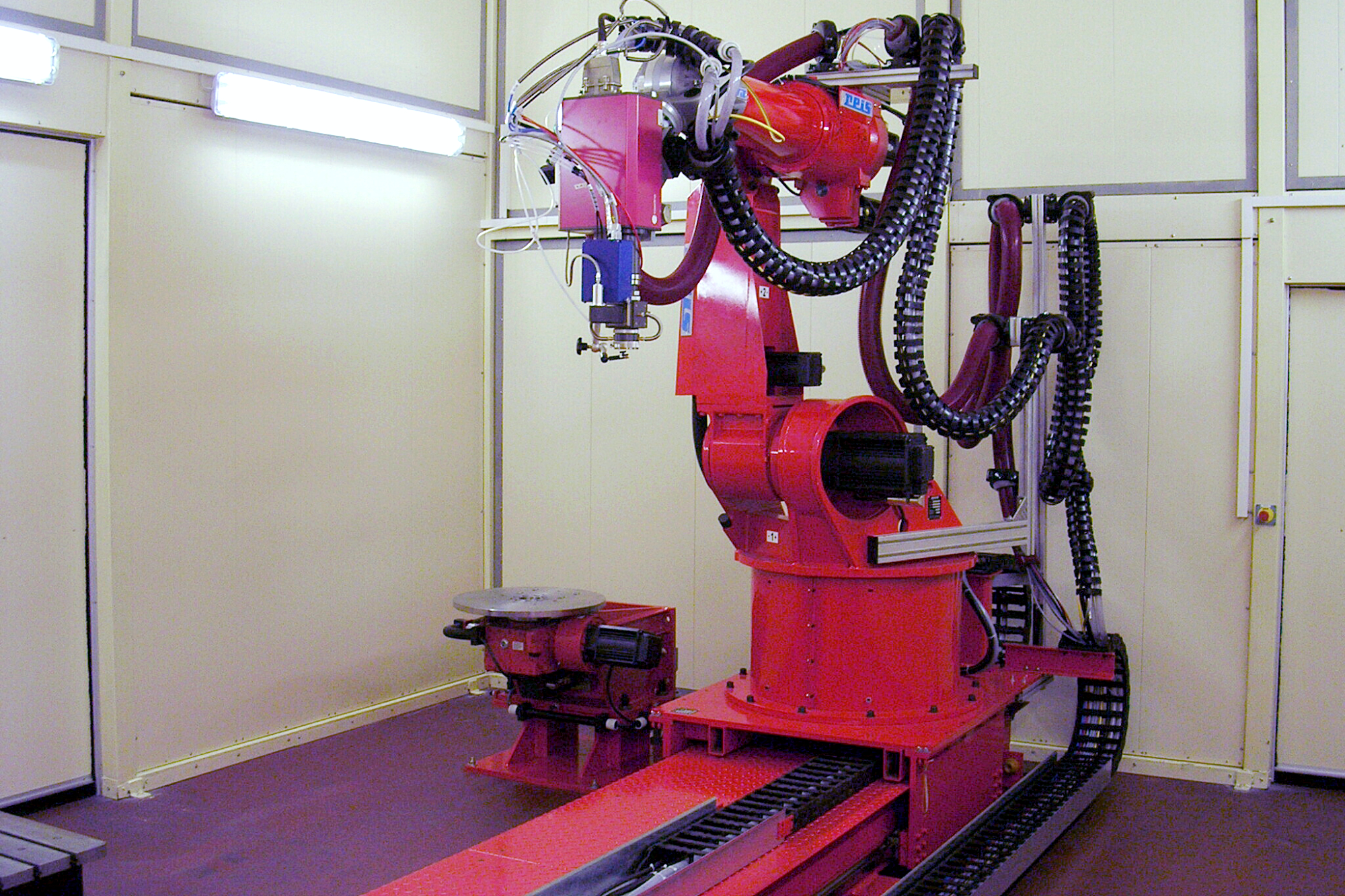

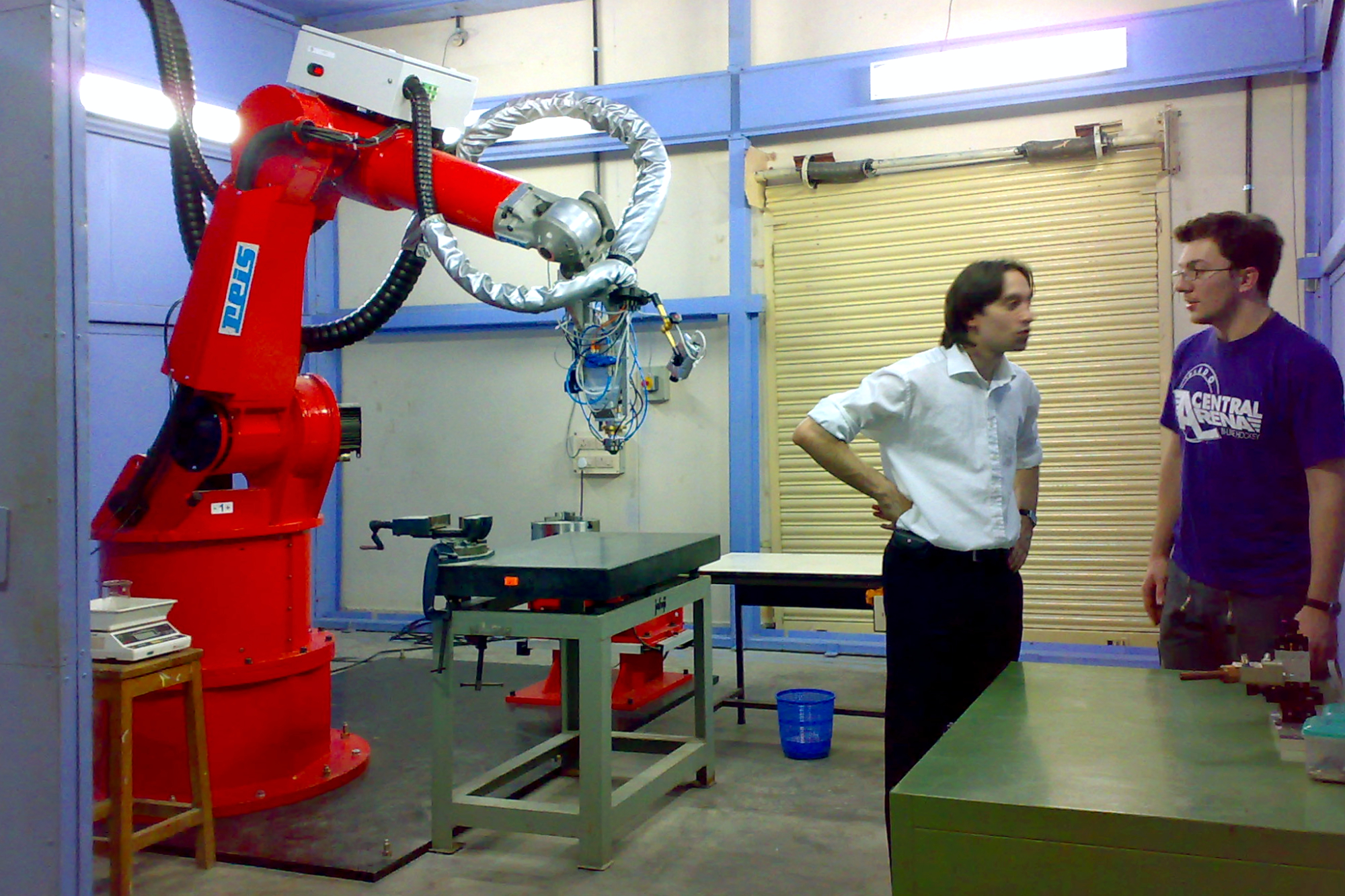

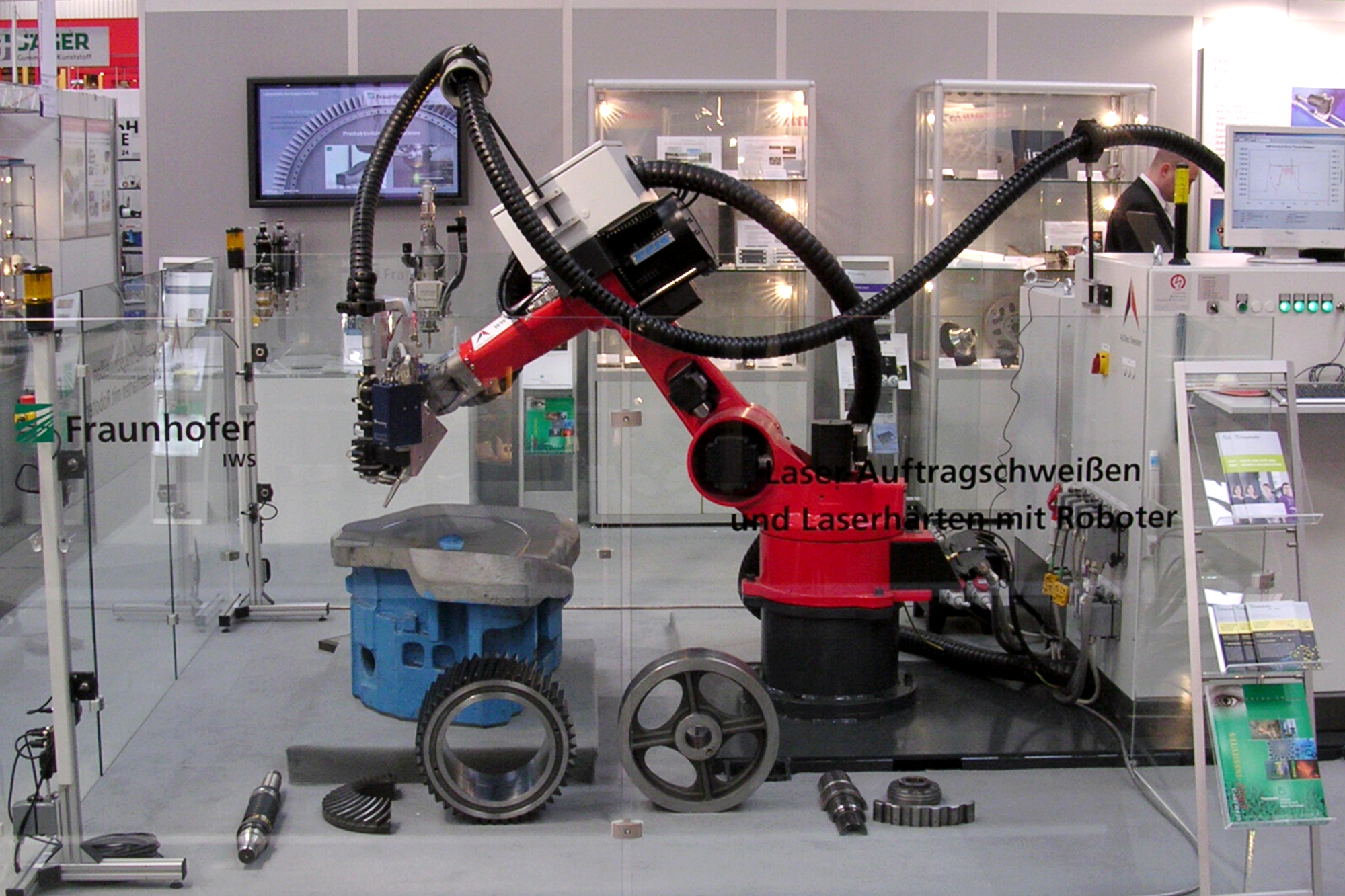

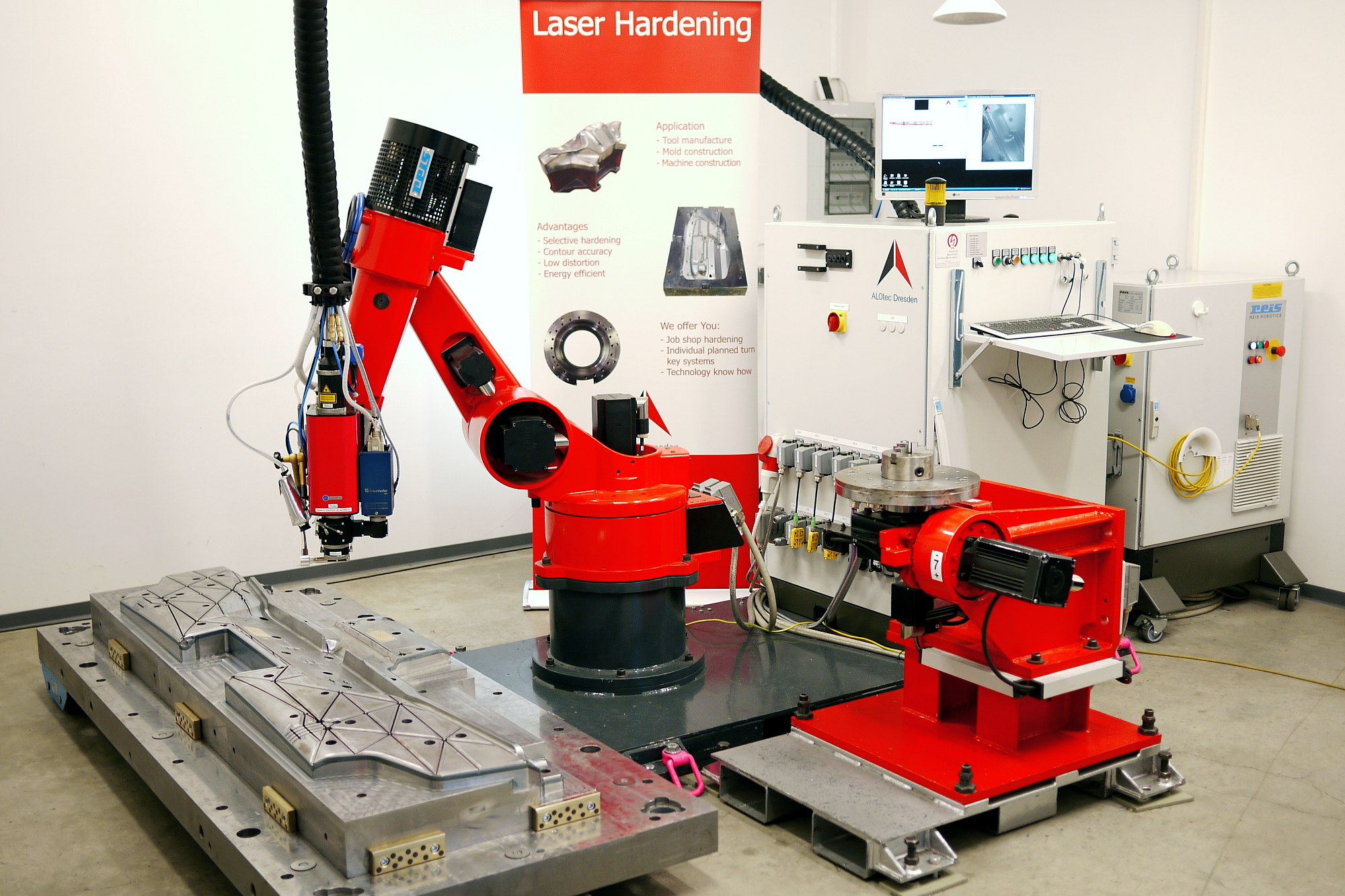

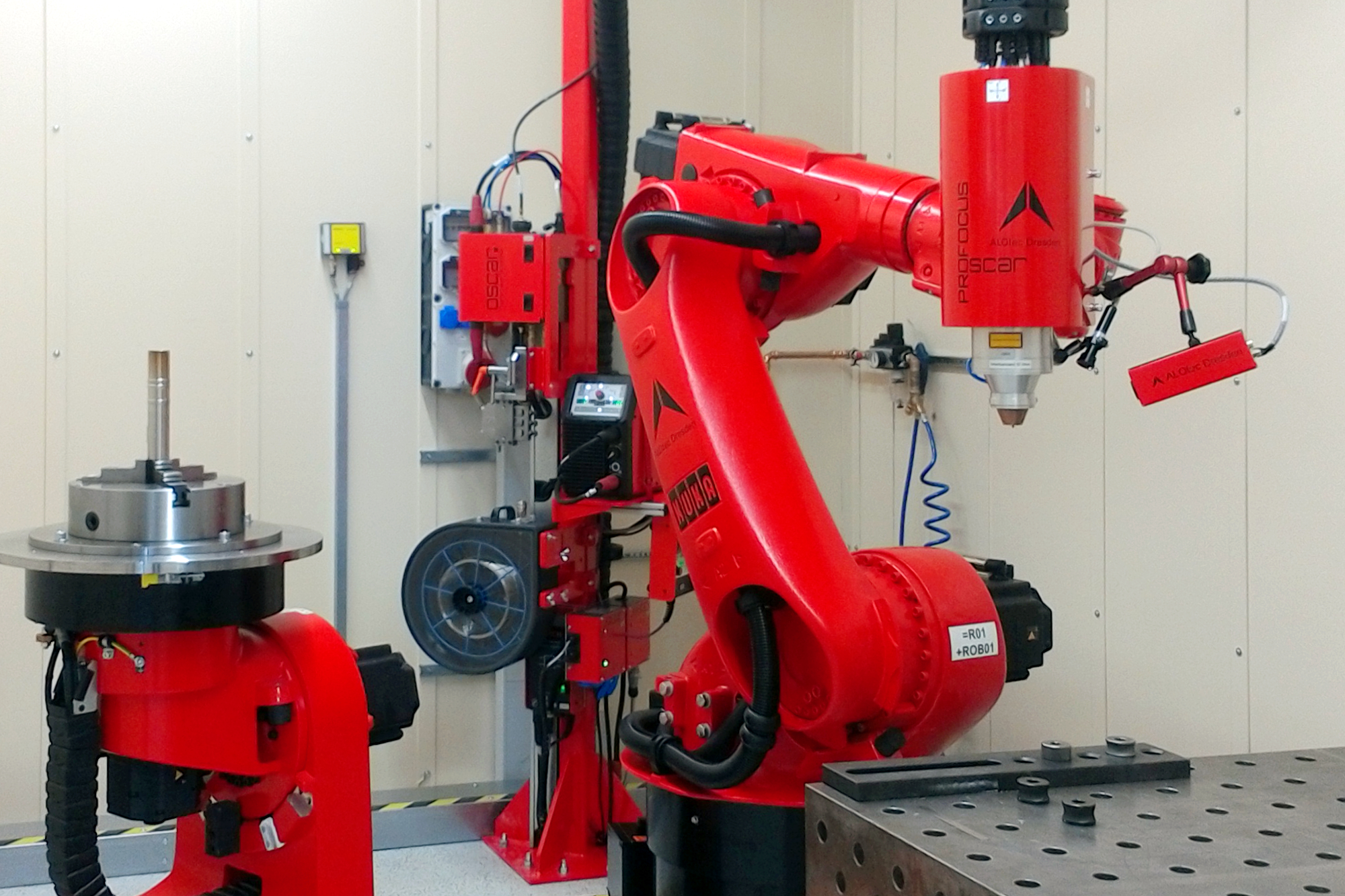

Installation of the first industrial robot for contract manufacturing at ALOtec Dresden GmbH.

-

2004

First use of a diode laser from Laserline.

-

2004

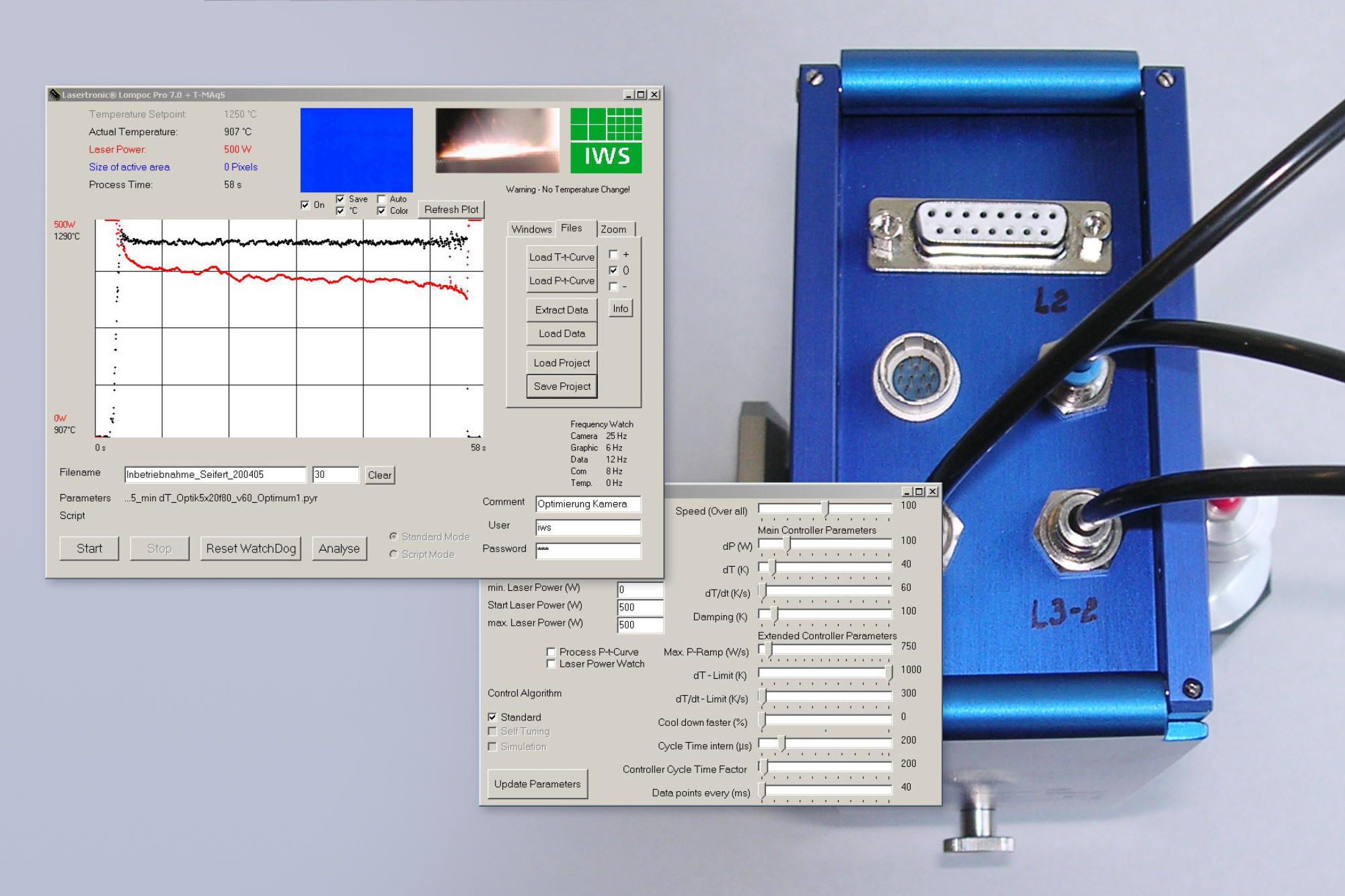

Integration of E-MAqS laser power control.

-

2004

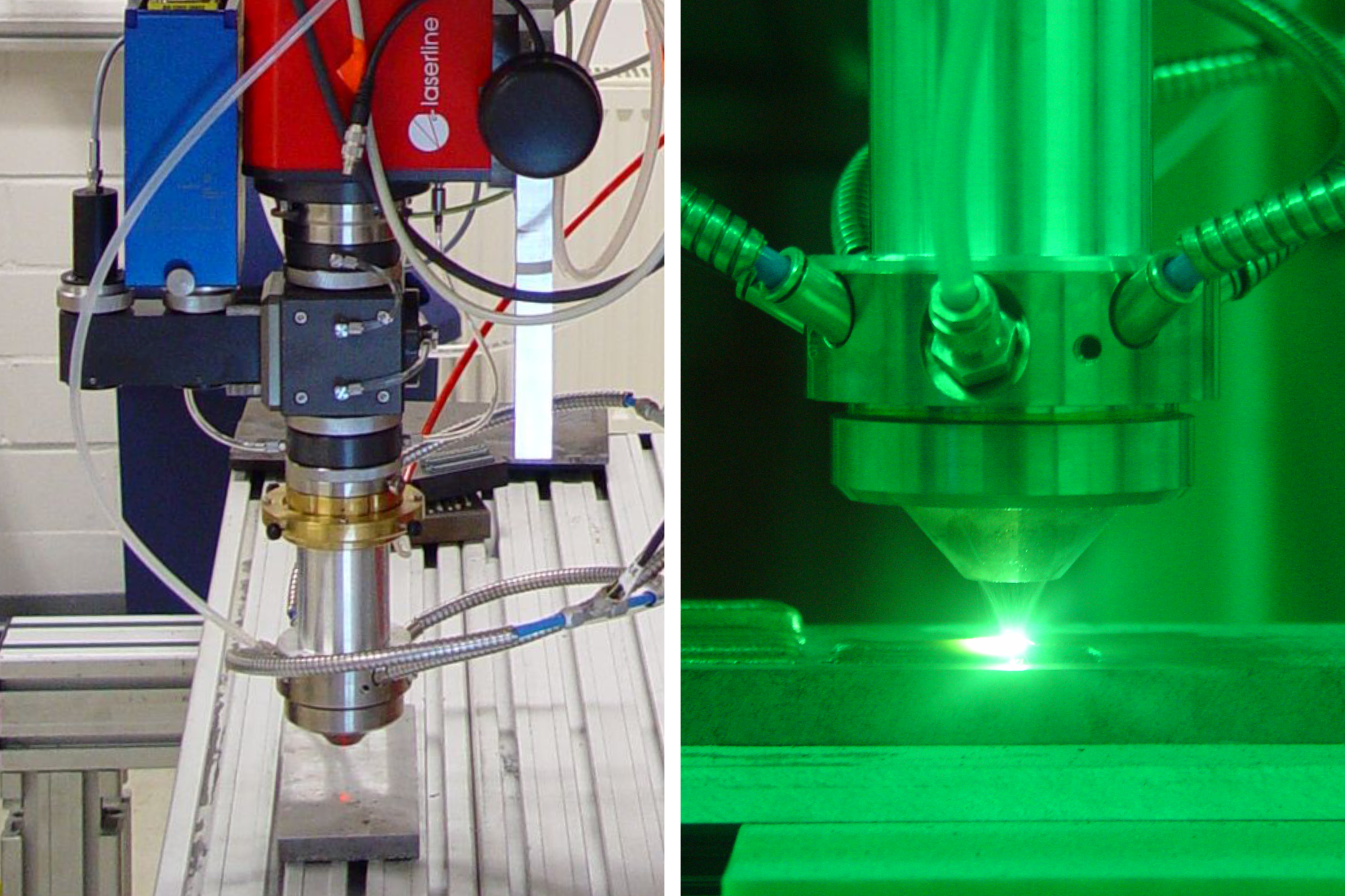

First trials with the laser powder cladding process.

-

2005

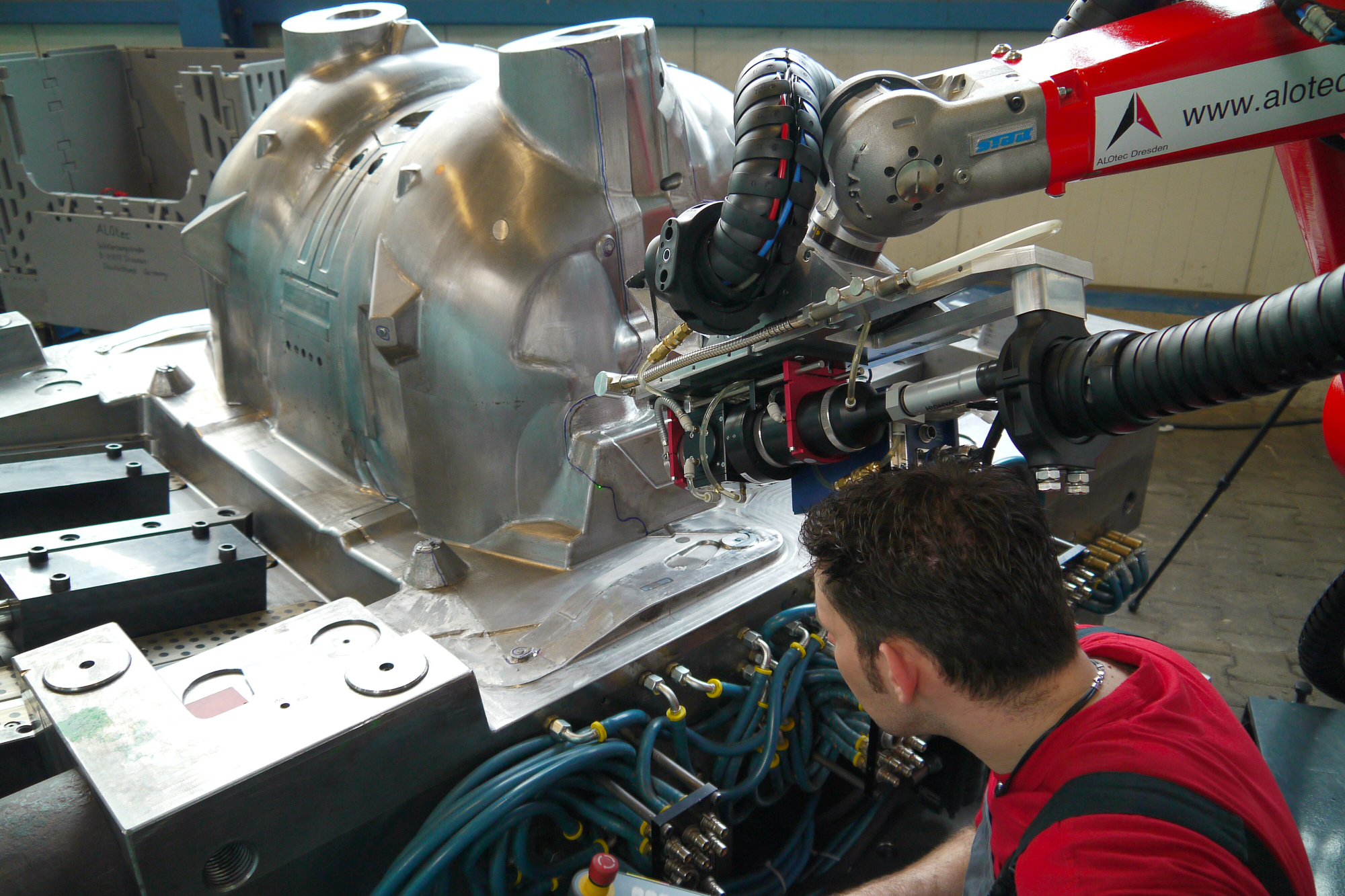

Delivery of the first robot system for laser hardening and laser powder cladding to Härterei Gerster AG in Switzerland.

-

2007

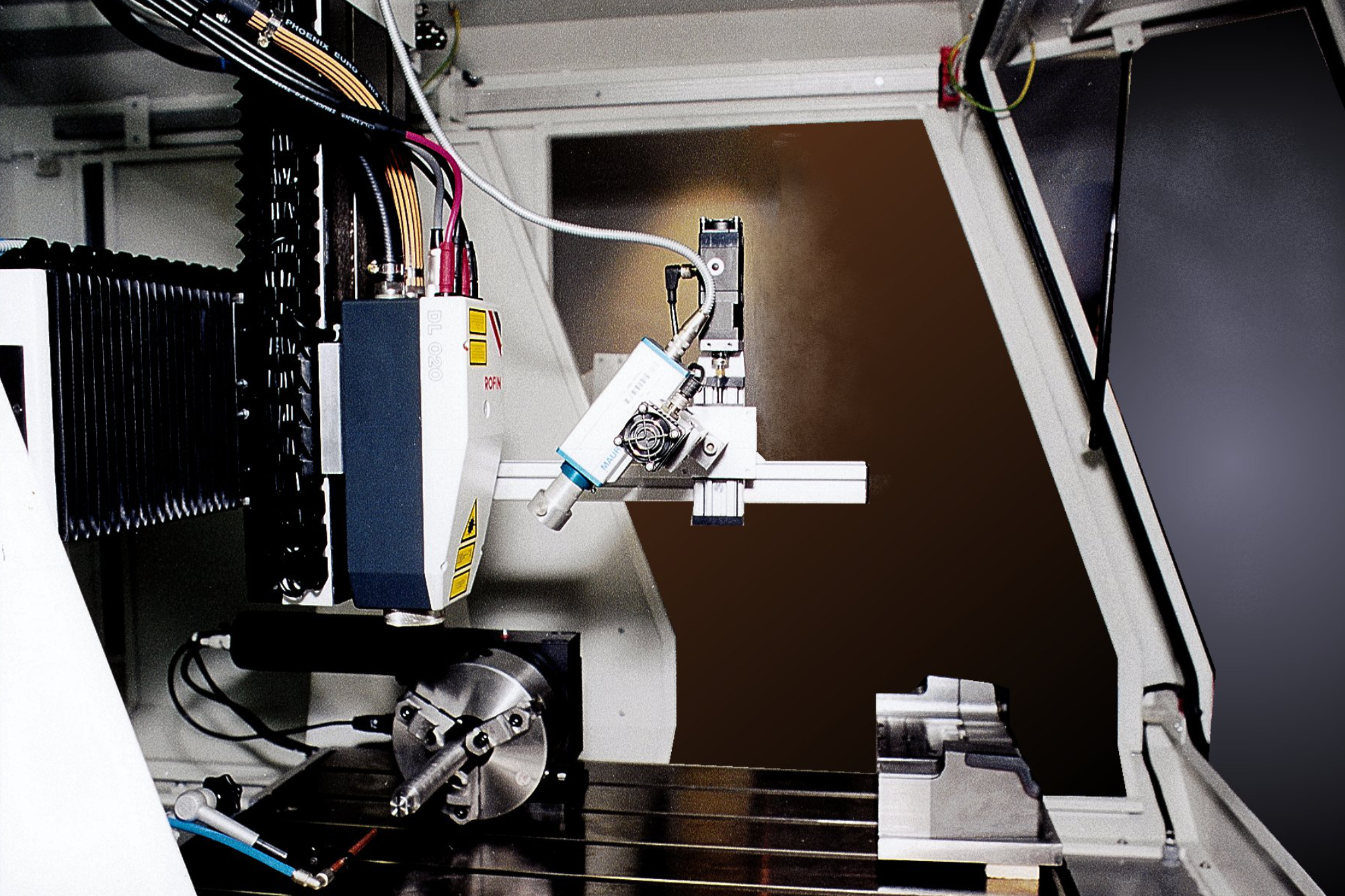

First delivery of a system for hardening and cladding with a fiber-coupled diode laser.

-

2009

First delivery of a system for hardening with scanner optics.

-

2010

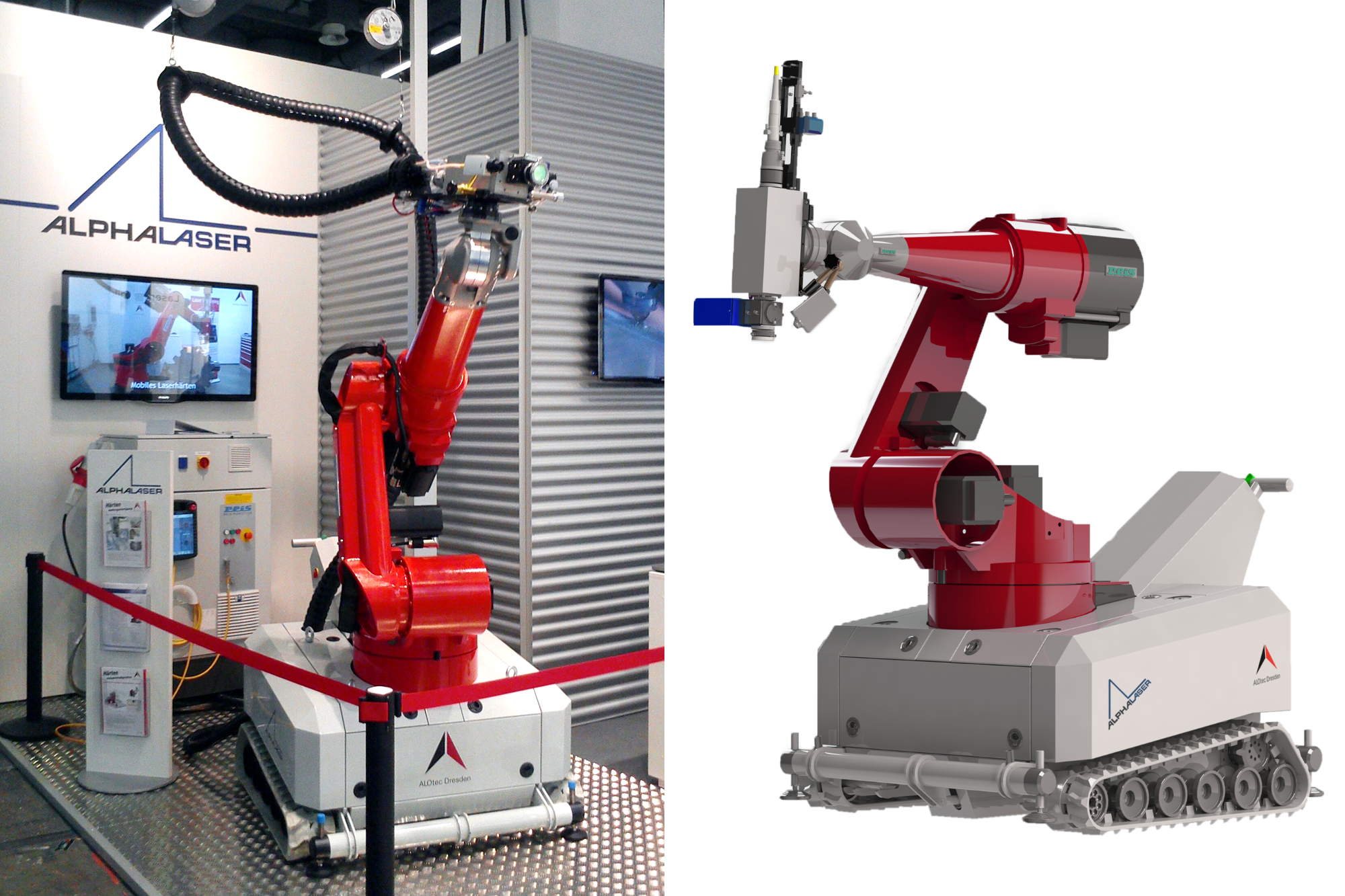

Presentation of the first mobile robot system for laser hardening at the Hannover Trade Fair.

-

2010

ALOtec Dresden intensifies laser cladding with the filler material wire.

-

2011

Relocation to a spacious production hall in the Kesselsdorf industrial estate on the outskirts of Dresden.

-

2011

First mobile application for laser hardening.

-

2011

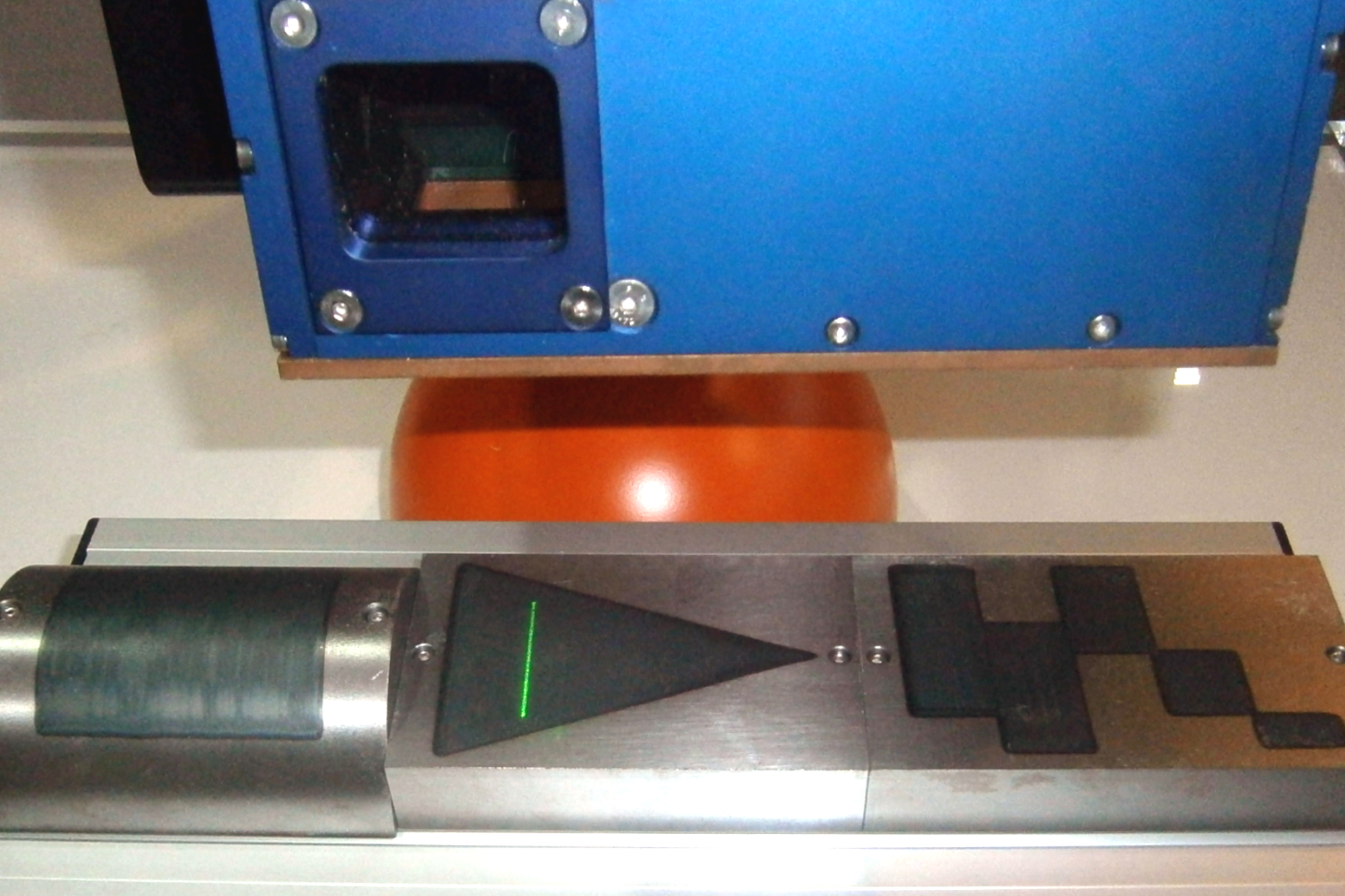

Integration of the first 1D zoom optics at ALOtec Dresden.

-

2013

Use of the new 2D zoom optics.

-

2013

First mobile laser processing system on a crawler – a joint project between ALOtec Dresden and Alphalaser.

-

2017

Delivery of the first system for laser cladding with wire to Adam Opel AG.

-

2018

Use of new zoom optics with round spot in laser powder cladding.

-

2018

Installation of a second ALOtec laser system in Japan.

-

2020

Use of the first system for additive manufacturing with ALOtwin processing optics.

-

2020

Completion of the new hybrid laser system ALOhybrid for stationary and mobile applications.

-

2021

Delivery of a laser system with ALOpowderID processing optics for internal laser cladding.

-

2022

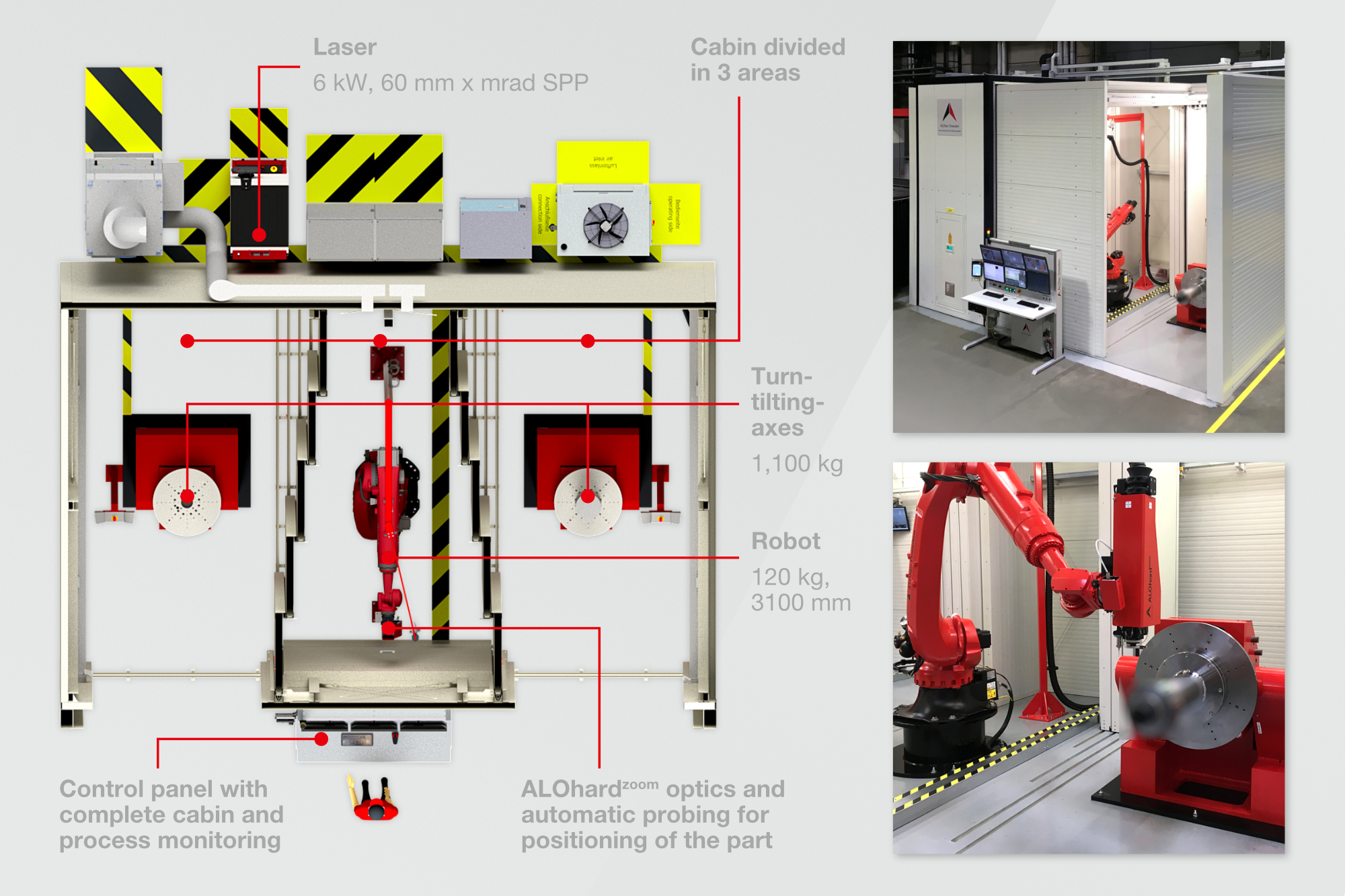

First system with 2 processing stations and automatic geometry detection (groove recognition).

-

2023

Certification of the ALOprotect5 mobile laser safety walls with top values.

ALOtec – News

We are up to date

We like to share our experiences.

Let’s talk.

Our daily work with laser technology and robotics in contract manufacturing and research produces many new innovations. You can benefit from them!